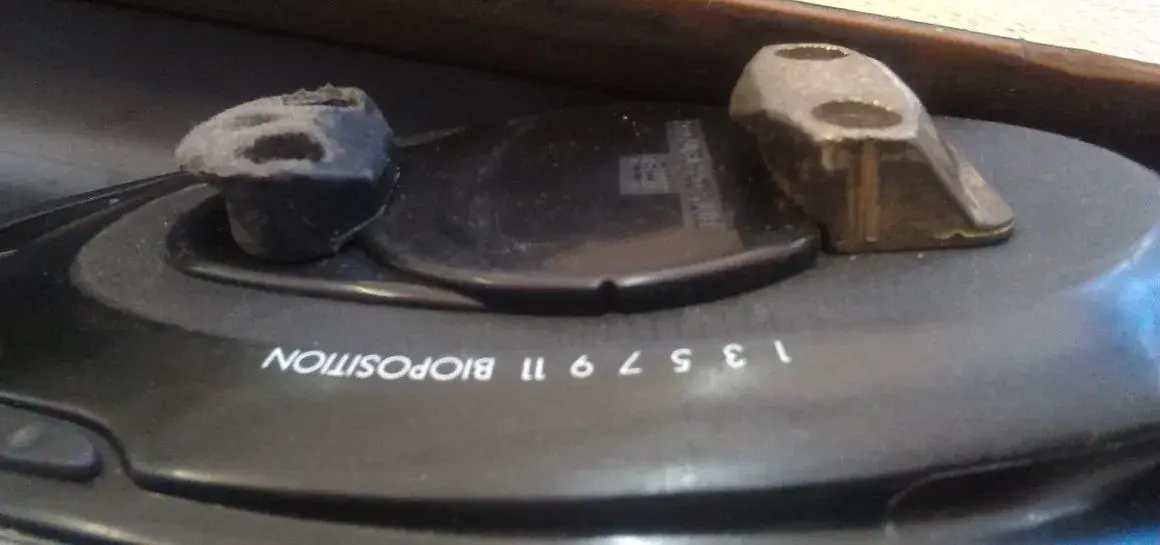

I recently realised i was in trouble with the wear on my front cams so I decided to make up my own Epoxy resin / carbon fibre ones .

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Time TBT cleats

- Thread starter latman

- Start date

rusty bodie

Senior Retro Guru

- Feedback

- View

Re:

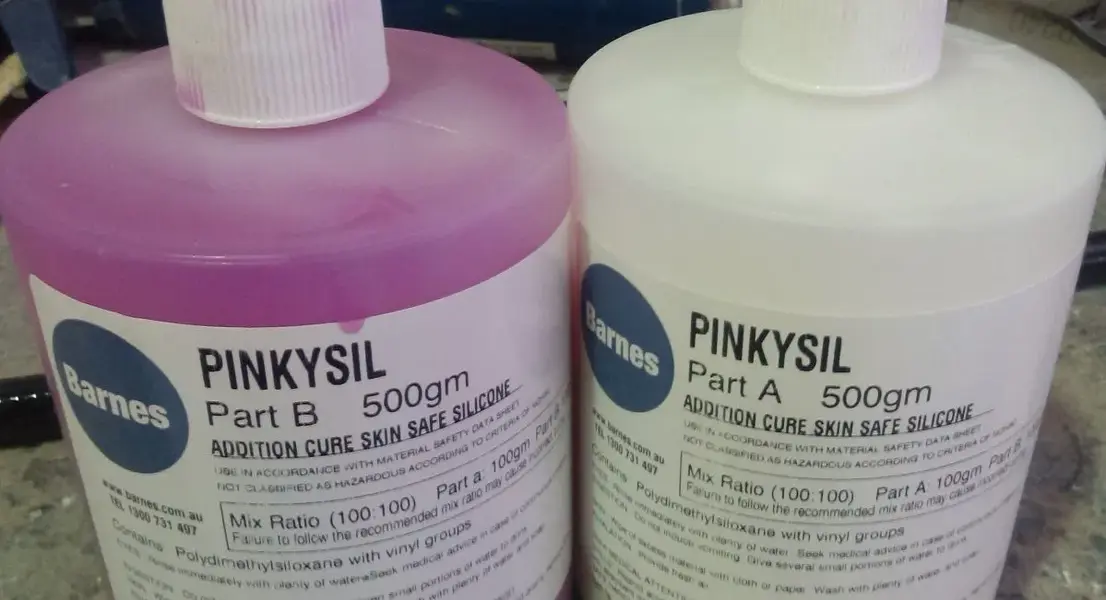

is that the same skin safe stuff they use to make those clone-a-willy kits?? i'd need to be sure of it's non-caustic properties before giving this a bash. :shock:

on a safer note, yes the time cleats are becoming a bit thin on the ground of late. the mk2 version of the forward cleat was made in alloy as the mk1 plastic ones got easily ruined, as you've no doubt found out.

what kind of caust, er, cost is your willy kit, ahem. . . silicone moulding kit??

is that the same skin safe stuff they use to make those clone-a-willy kits?? i'd need to be sure of it's non-caustic properties before giving this a bash. :shock:

on a safer note, yes the time cleats are becoming a bit thin on the ground of late. the mk2 version of the forward cleat was made in alloy as the mk1 plastic ones got easily ruined, as you've no doubt found out.

what kind of caust, er, cost is your willy kit, ahem. . . silicone moulding kit??

I suggest no but why don't you just try prove me wrong ,the advantage of machining one up is the large amont of billet materials available , other than that you need either a 4d cutter or a complex fixture to hold a small item so a 3d cutter can make the undercut , I wonder why time cast them back in the day ?

I'd suspect they were cast (or injection moulded) as that was the cheapest way to produce that sort of volume of parts. A 4 axis machine in the 80s was slow and expensive. Multi Million pound investment sort of thing.

I know you can buy a 4 axis machine for a couple of grand these days, it'll only have something like a 200*200*75 capacity, but what else do you need in your home workshop? (I know of at least 3 people with 3 and/or 4 axis machines at home)

And fixturing wouldn't be particularly tricky seeing as you have a couple of locating holes in the middle.

Could get it 3D printed as well.

I know you can buy a 4 axis machine for a couple of grand these days, it'll only have something like a 200*200*75 capacity, but what else do you need in your home workshop? (I know of at least 3 people with 3 and/or 4 axis machines at home)

And fixturing wouldn't be particularly tricky seeing as you have a couple of locating holes in the middle.

Could get it 3D printed as well.

For the small number needed 3D scanning and machining will be too expensive and the ABS plastics that are used for 3D printing would be too weak IMOmattr":thn82zxs said:I'd suspect they were cast (or injection moulded) as that was the cheapest way to produce that sort of volume of parts. A 4 axis machine in the 80s was slow and expensive. Multi Million pound investment sort of thing.

I know you can buy a 4 axis machine for a couple of grand these days, it'll only have something like a 200*200*75 capacity, but what else do you need in your home workshop? (I know of at least 3 people with 3 and/or 4 axis machines at home)

And fixturing wouldn't be particularly tricky seeing as you have a couple of locating holes in the middle.

Could get it 3D printed as well.

Your first sentence makes no sense. 3Dlatman":28auzai5 said:For the small number needed 3D scanning and machining will be too expensive and the ABS plastics that are used for 3D printing would be too weak IMO

scanning and then machining is the go to method for small volume prototyping of this sort of thing, nothing else comes close on price or accuracy. And costs have come down massively in the last couple of years as well. (Probably not far off halving as far as 3D scanning goes.)

And as far as 3D printing goes, you need to choose the right material.........

Similar threads

- Replies

- 4

- Views

- 556

- Replies

- 14

- Views

- 697

- Replies

- 1

- Views

- 172