- Feedback

- View

So I want to remove some eyelets as it time to get on with a frame I've had longer than I thought.

I know I could junior hacksaw them off and sand down, but my hands really bugger up doing that, they do with just cutting wood as it something about the grip.

So I have a dremel and plant of bits of all shapes and sizes. I used them randomly to do all sorts but to be honest its often hit and hope as there are so many of them.

But the frame is thin and I'd rather get it done easily rather than try through all the parts and bugger the stays up.

So which do I use to chop it off, grind what's left off, polish the area ups a bit for a better finish.

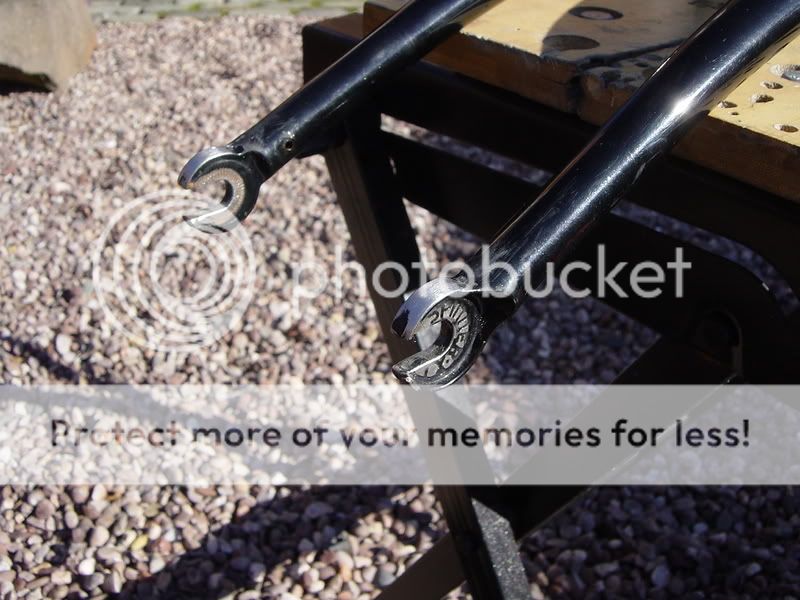

First one is this

The other is a wider seat stay style a bit like these until I get a picture

I know I could junior hacksaw them off and sand down, but my hands really bugger up doing that, they do with just cutting wood as it something about the grip.

So I have a dremel and plant of bits of all shapes and sizes. I used them randomly to do all sorts but to be honest its often hit and hope as there are so many of them.

But the frame is thin and I'd rather get it done easily rather than try through all the parts and bugger the stays up.

So which do I use to chop it off, grind what's left off, polish the area ups a bit for a better finish.

First one is this

The other is a wider seat stay style a bit like these until I get a picture