synchronicity

Senior Retro Guru

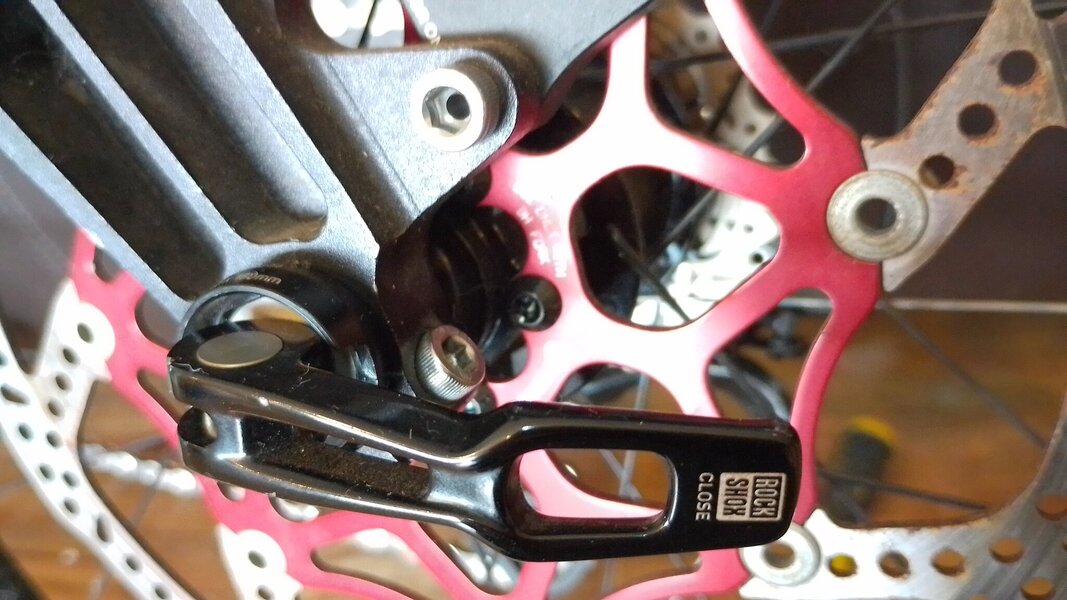

Going over my old Marzocchi 888 fork, I noticed rust at the bottom of the legs where the inserts for the axle pinch bolts go.

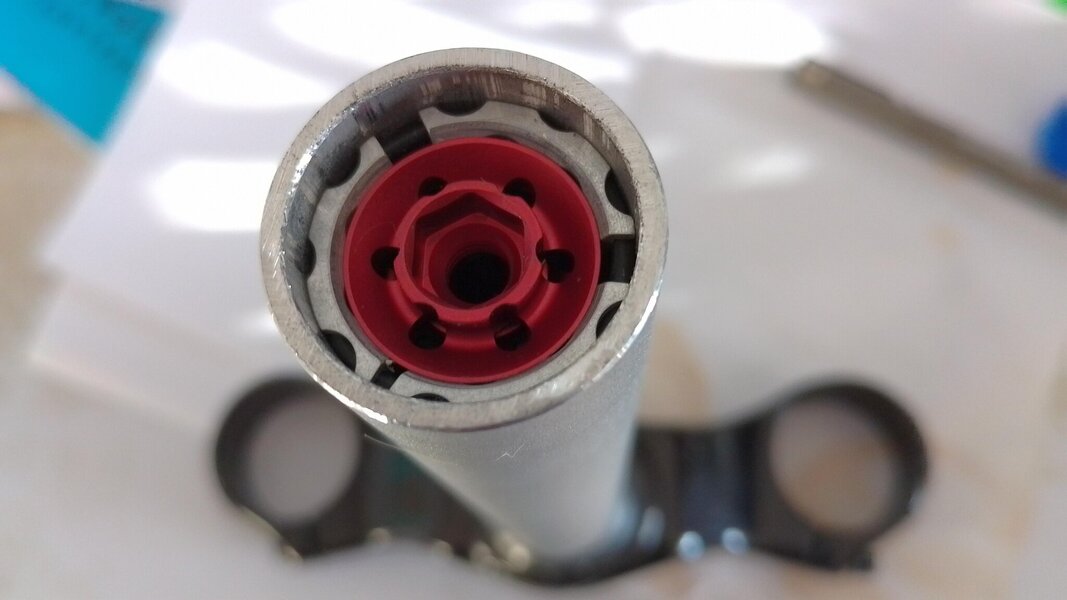

I removed them just in case, more as a preventative measure really, half expecting them to be crumbling piles of rust.

They seem to be in adequate condition. Replacing them anyway as they're already out now.

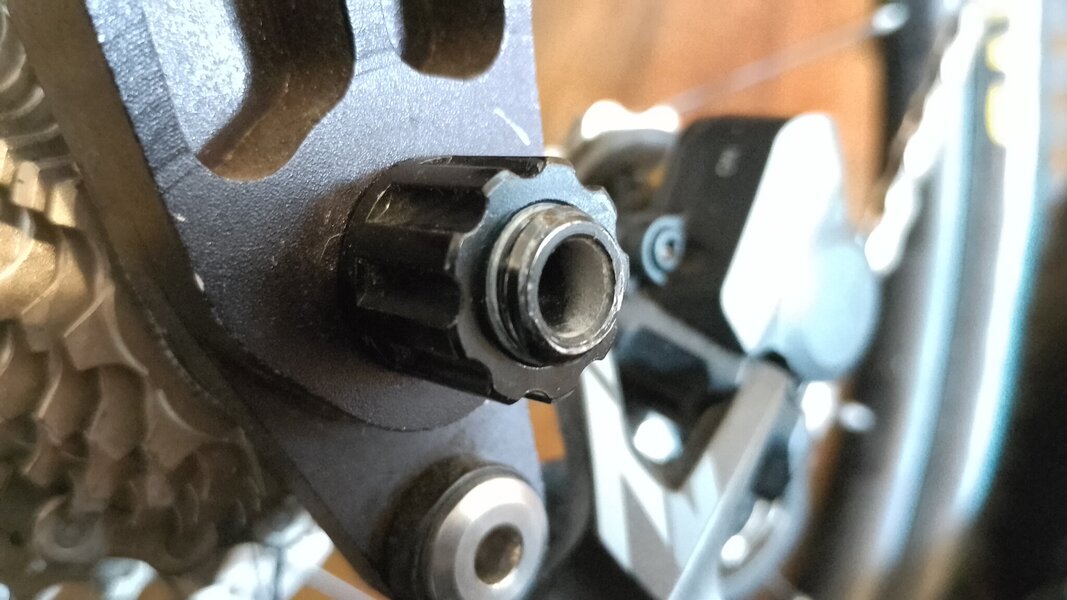

Oh yeah, and I got a pack of 10 cheapy alloy barrel adjuster bolts.

I removed them just in case, more as a preventative measure really, half expecting them to be crumbling piles of rust.

They seem to be in adequate condition. Replacing them anyway as they're already out now.

Oh yeah, and I got a pack of 10 cheapy alloy barrel adjuster bolts.

Attachments

Last edited: