I’ve been rebuilding a set of Manitou Answer M Sports and before going for new elastomers I thought I’d try industrial die springs (rather than wire based springs like Wings).

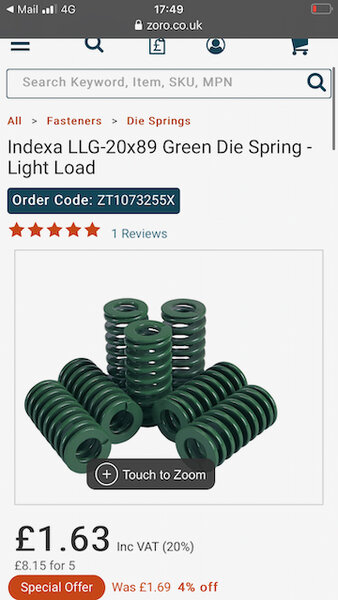

They were super cheap at £1.63 each (though I’ve bought various sizes and spring levels to experiment). They don’t bounce, so they don’t pogo. The ‘light’ springs seem perfect in a 20mm x 89mm size. I’ve reused all the washers at either end and used an old elastomer for the rebound side. At my weight (70kg) they don’t quite fully travel (maybe 30mm) so I’ve also ordered extra light load to try next,but they’re not coming quickly as they’re coming from China, next month.

I’m sure I’m not the first to try this, but personally want to carry on trying experimenting. They MIGHT break I guess but they are so heavy duty this seems unlikely.

They were super cheap at £1.63 each (though I’ve bought various sizes and spring levels to experiment). They don’t bounce, so they don’t pogo. The ‘light’ springs seem perfect in a 20mm x 89mm size. I’ve reused all the washers at either end and used an old elastomer for the rebound side. At my weight (70kg) they don’t quite fully travel (maybe 30mm) so I’ve also ordered extra light load to try next,but they’re not coming quickly as they’re coming from China, next month.

I’m sure I’m not the first to try this, but personally want to carry on trying experimenting. They MIGHT break I guess but they are so heavy duty this seems unlikely.