After a couple of hundred miles on my fixed pre war Dawes I noticed that the Bb was moving to the right. It went about a cm!

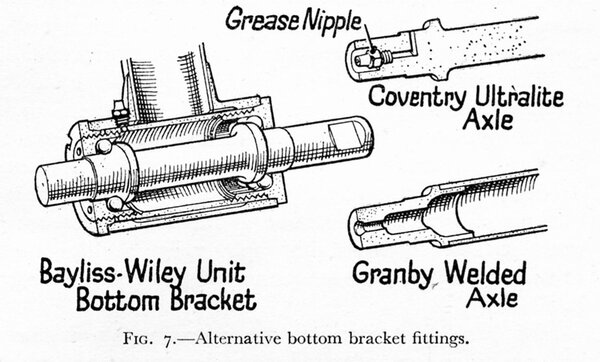

I pushed it back and finished the ride. When I took it out to check I realised that the BB was threaded into a sleeve. It was that which was moving. There are absolutely no signs of any brazing etc . Am I correct in assuming that this sleeve would have been pressed in.

Am I missing something.

The BB shell looks just like a normal BB albeit with no threads and about 4mm greater in diameter.

I pushed it back and finished the ride. When I took it out to check I realised that the BB was threaded into a sleeve. It was that which was moving. There are absolutely no signs of any brazing etc . Am I correct in assuming that this sleeve would have been pressed in.

Am I missing something.

The BB shell looks just like a normal BB albeit with no threads and about 4mm greater in diameter.