You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Geoff Apps - Cleland

- Thread starter Timberpeg

- Start date

- Feedback

- View

Good luck, I wish you well. I can measure the approximate dimensions/angles of the spoke head that Geoff's machine produces if that would be helpful?Thanks for the update Graham - and to Geoff for his input. I’ll do some prototyping and see where it leads me.

Here is an inexpensive arbour press, that if fitted with a custom made jig could probably be used to create the bends in the end of a pre-cut spoke?

Vevor 1ton arbor press on eBay

When you click on links to various merchants on this site and make a purchase, this can result in this site earning a commission. Affiliate programs and affiliations include, but are not limited to, the eBay Partner Network.

- Feedback

- View

Here are two photos showing the 700C front wheel of a Cleland Landseer showing the Qwikspokes at the hub.

Note that the front wheel had been built using a 1 cross pattern on the roller-brake side and radial spokes on the other side. In all 20 spokes have been used. Given the 700C/622mm rim and intended heavy off-road use this is relatively a low number of spokes. The fact that the wheel is still true and no spokes have broken after several years of use is testament to the inherent strength of this method.

Note that the front wheel had been built using a 1 cross pattern on the roller-brake side and radial spokes on the other side. In all 20 spokes have been used. Given the 700C/622mm rim and intended heavy off-road use this is relatively a low number of spokes. The fact that the wheel is still true and no spokes have broken after several years of use is testament to the inherent strength of this method.

- Feedback

- View

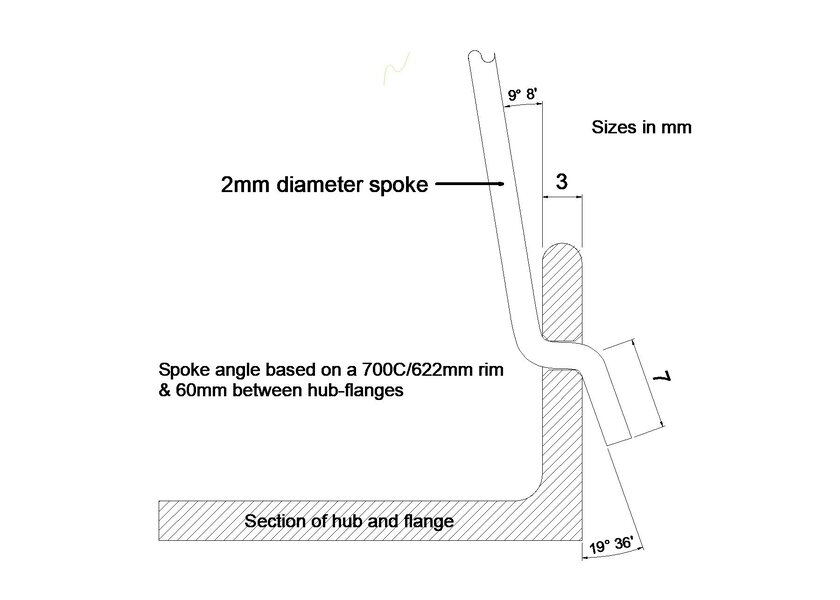

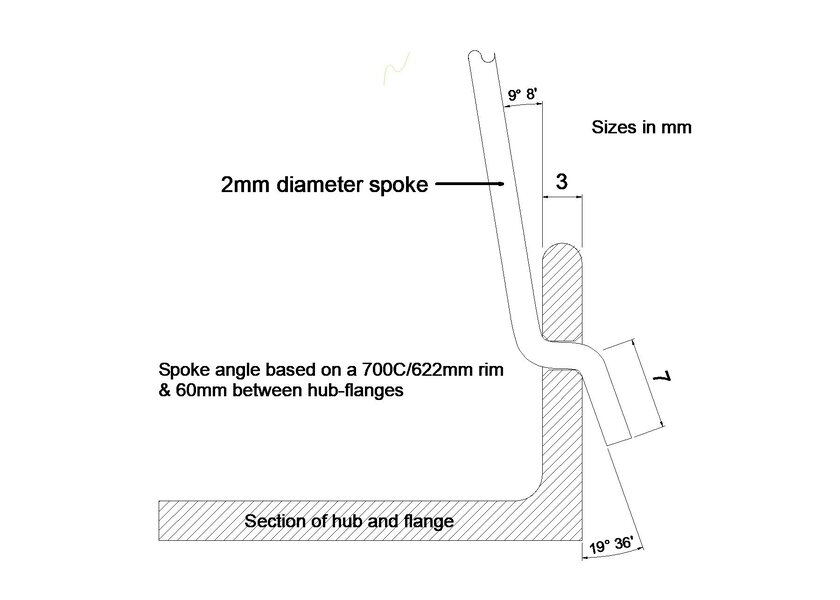

Here are the spoke dimensions as used on the wheels in the above photos. The same spokes have been used to fit both the inside and outside of the flanges.

The drawing shows a spoke as fitted on the inside of the of the drum brake side of the wheel. To make sure that the same spoke would also fit on the outside of the flange, the end of each spoke has been angled about ten degrees away from the main spoke axis. Because of this, the spokes positioned on the outside of the hub (as shown in the photos) seat more neatly with their ends closer to the flange.

Note that these spokes would not seat as well if they were built into a narrower flange. Also, the spoke angle given will change with different rim diameters and hub-flange spacing.

The drawing shows a spoke as fitted on the inside of the of the drum brake side of the wheel. To make sure that the same spoke would also fit on the outside of the flange, the end of each spoke has been angled about ten degrees away from the main spoke axis. Because of this, the spokes positioned on the outside of the hub (as shown in the photos) seat more neatly with their ends closer to the flange.

Note that these spokes would not seat as well if they were built into a narrower flange. Also, the spoke angle given will change with different rim diameters and hub-flange spacing.

Hi Graham. Thanks for the excellent photos and the detailed drawing. I think you’ve answered several design questions around this.

I found a couple of videos like this, Calculating bend and setback allowance, that also help to explain how the overall length of the spoke can be calculated.

Amazing. Twenty spokes with 1-cross + radial combination sounds like it couldn’t possibly work, especially on an MTB, but it obviously does.

I bought a small hand tool (used by lawn mower mechanics) to make a few test items. It’s possible to produce a few emergency spokes with it, but not very consistently.

A manufacturer of wire bending tools demoed a very precise tool for me: it can bend two spokes at a time so it’s quite efficient. However, it costs more than a manual spoke roller and die, which defeats my DIY goal. I’m also checking out a few other bending tools in the €50-100 price range.

I’m still shopping around for an arbor press and thinking about tooling. This may well be the best option.

I found a couple of videos like this, Calculating bend and setback allowance, that also help to explain how the overall length of the spoke can be calculated.

Amazing. Twenty spokes with 1-cross + radial combination sounds like it couldn’t possibly work, especially on an MTB, but it obviously does.

I bought a small hand tool (used by lawn mower mechanics) to make a few test items. It’s possible to produce a few emergency spokes with it, but not very consistently.

A manufacturer of wire bending tools demoed a very precise tool for me: it can bend two spokes at a time so it’s quite efficient. However, it costs more than a manual spoke roller and die, which defeats my DIY goal. I’m also checking out a few other bending tools in the €50-100 price range.

I’m still shopping around for an arbor press and thinking about tooling. This may well be the best option.

27motorhead

Senior Retro Guru

- Feedback

- View

What a great thread! Look forward to seeing what you end up building/making/modifying @Timberpeg

Similar threads

- Replies

- 5

- Views

- 1K

- Replies

- 0

- Views

- 956

- Replies

- 1

- Views

- 480