Just bought a 'unior' branded spoke tensiometer. Thought it would be a useful exercise in reviewing it for those interested.

After a rear wheel fight with a branch a couple of weeks back, putting in a serious wheel wobble, I started to read up about wheel truing. Initially trued it reasonably well using the bike frame as a truing guide. Having read about using the 'pinging' of spokes to check for tension balance it was fairly clear the balance was all over the place. Tried using a guitar tuner app to record the frequency, but it was too impractical to use. So I bought Roger Musson's wheelbuilding book and, as instructed in the book, have just finished building a truing stand, dishing tool and nipple driver (all out of bits and pieces in the garage - so no direct cost).

I decided to use the money saved to buy a tensiometer - but which one! They range in cost from £17 to many hundreds. Entry level middle ground appears to be dominated by the Park Tool version (about £70). However, there was an offer on the 'unior' branded version (£67). It had good reviews, came in a box, and included a calibration bar, so i splashed out and bought that one.

Cannot compare it directly with the other brands, having never used them, but 'out of the box' I would say the unior one is well made in general.

The deflection scale runs from 0 to 96, with the dial pointer not fully zeroed out of the box (reading -1). It is adjustable though.

The calibration bar is flagged as 62 units and when placed in the meter, it does indeed settle at 62. Spring tension can be adjusted if need be. There is a spoke gauge, which appears accurate for my butted spokes (2/1.8/2).

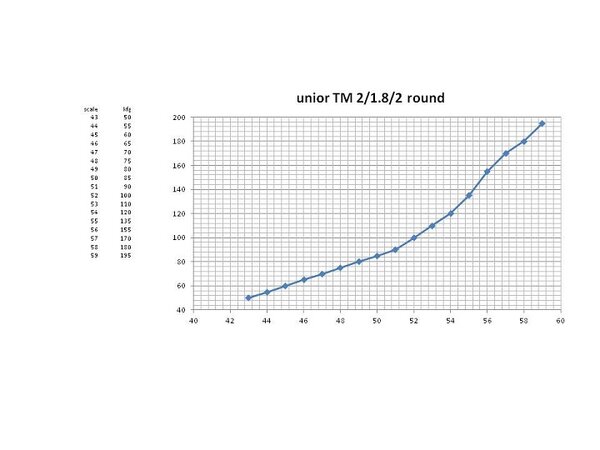

There is a deflection scale to 'kilogram force' units table for various spoke types.

Have plotted the scale conversion table for a 2/1.8/2 butted spoke. Does not appear to have a smooth relationship. However, discussion the internet indicates that the conversion from dial scale to tension, for any of the available tensiometers, is unlikely to be accurate and is only a guide. When using tensiometers, it is the 'relative' difference in tension that is the more practical indicator. When plotting data it is probably worth converting to 'apparent' tension, because of the non linear conversion. Will give example later - just off to make some rice pudding!

After a rear wheel fight with a branch a couple of weeks back, putting in a serious wheel wobble, I started to read up about wheel truing. Initially trued it reasonably well using the bike frame as a truing guide. Having read about using the 'pinging' of spokes to check for tension balance it was fairly clear the balance was all over the place. Tried using a guitar tuner app to record the frequency, but it was too impractical to use. So I bought Roger Musson's wheelbuilding book and, as instructed in the book, have just finished building a truing stand, dishing tool and nipple driver (all out of bits and pieces in the garage - so no direct cost).

I decided to use the money saved to buy a tensiometer - but which one! They range in cost from £17 to many hundreds. Entry level middle ground appears to be dominated by the Park Tool version (about £70). However, there was an offer on the 'unior' branded version (£67). It had good reviews, came in a box, and included a calibration bar, so i splashed out and bought that one.

Cannot compare it directly with the other brands, having never used them, but 'out of the box' I would say the unior one is well made in general.

The deflection scale runs from 0 to 96, with the dial pointer not fully zeroed out of the box (reading -1). It is adjustable though.

The calibration bar is flagged as 62 units and when placed in the meter, it does indeed settle at 62. Spring tension can be adjusted if need be. There is a spoke gauge, which appears accurate for my butted spokes (2/1.8/2).

There is a deflection scale to 'kilogram force' units table for various spoke types.

Have plotted the scale conversion table for a 2/1.8/2 butted spoke. Does not appear to have a smooth relationship. However, discussion the internet indicates that the conversion from dial scale to tension, for any of the available tensiometers, is unlikely to be accurate and is only a guide. When using tensiometers, it is the 'relative' difference in tension that is the more practical indicator. When plotting data it is probably worth converting to 'apparent' tension, because of the non linear conversion. Will give example later - just off to make some rice pudding!