You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

milling slots in cranks to lighten them

- Thread starter littleblackflash

- Start date

- Feedback

- View

Milling clamps and such as on WD's Marin is one thing, but I have seen first hand what can happen to a mans calf when a crank snaps. :shock: :shock: :shock:

I would certainly never ride modified cranks.

I would certainly never ride modified cranks.

poweredbypies

Old School Grand Master

- Feedback

- View

xerxes":21lnr0nl said:Used to see a fair amount of "drillium" on time trial bikes back in the 80s, brakes, seat posts, stems, derailleurs and cranks that were more hole than metal. When well done it looks great, but I'm not sure how safe it is. :shock:

Lots more: http://www.google.co.uk/search?newwindo ... 0QWzr4DYDA

That is beautifully done. Wouldnt ride it but would certainly love a set just to hang on the garage wall.

VTFoco2001

Retro Guru

My advice is not tot modify cranks by e.g. milling. The reason for this is that these parts are subjected tot low cycle fatigue. Unless you have designed the cranks yourselves you will be unaware of any stress concentrations and possible crack initiation.

Polishing though is an option to s(h)ave some grams.

Polishing though is an option to s(h)ave some grams.

jonthefish

Senior Retro Guru

- Feedback

- View

Looks a bit iffy to me, especially on something as subject to stress as cranks. Can't help thinking you'd save as much weight by taking a piss. But I guess that's not the point...

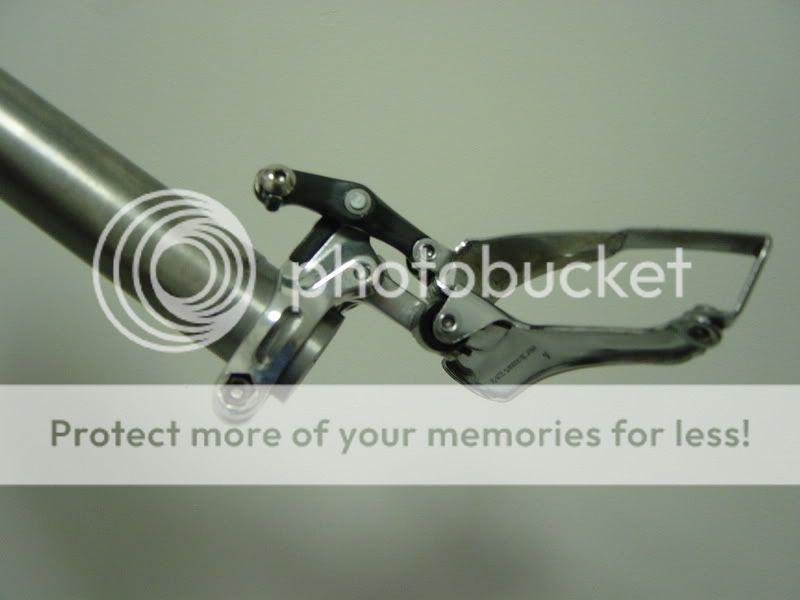

WD Pro":19uqdwdj said:littleblackflash":19uqdwdj said:I just brought another cannondale and the XT brake levers have a slot milled in the handle bar clamp which was another weight weenie trick.

WD

How are these done & where can I get it done?

Similar threads

- Replies

- 0

- Views

- 483