The Malcolm

Retro Guru

Over the summer I have been working on some headshok forks. I have overhauled a DD60 and two DL80's. Below is a few pictures of how I tackled the DL80

Both sets of forks below have the same DL80 oil and air damper inside them. The only difference between them is the one on the left doesn't have "V" brake mounts.

The tools I used are shown below

Pin spanner

Supercastle tool KT31

Red grease

Replacement seal kit HD166 (£3.99)

Fork oil 5WL

Bullet tool FT70

Shaft Clamps HDTL187

To remove the top cap I used a pin spanner to screw the cap off. (Please note leave the aluminium nut well alone. The aluminium nut is press fitted onto a spindle and if you rotate it with a spanner you could ruin it)

Once the top cap was removed below is the view inside. Then I let all the air out of the air piston and used the super castle tool to remove the cartridge.

Below is the supercastle tool in use. It takes a 3/8" socket wrench in the square hole in the top.

Once removed the oil damper is shown below

The air piston was still in the air damper I removed this by putting my hand over the top of the fork and putting a bit air into the damper and the piston shoots out. First time I did this it hit me in the face along with all the fork oil that had drained into the air cylinder - so be careful. There was also a return spring above the air piston.

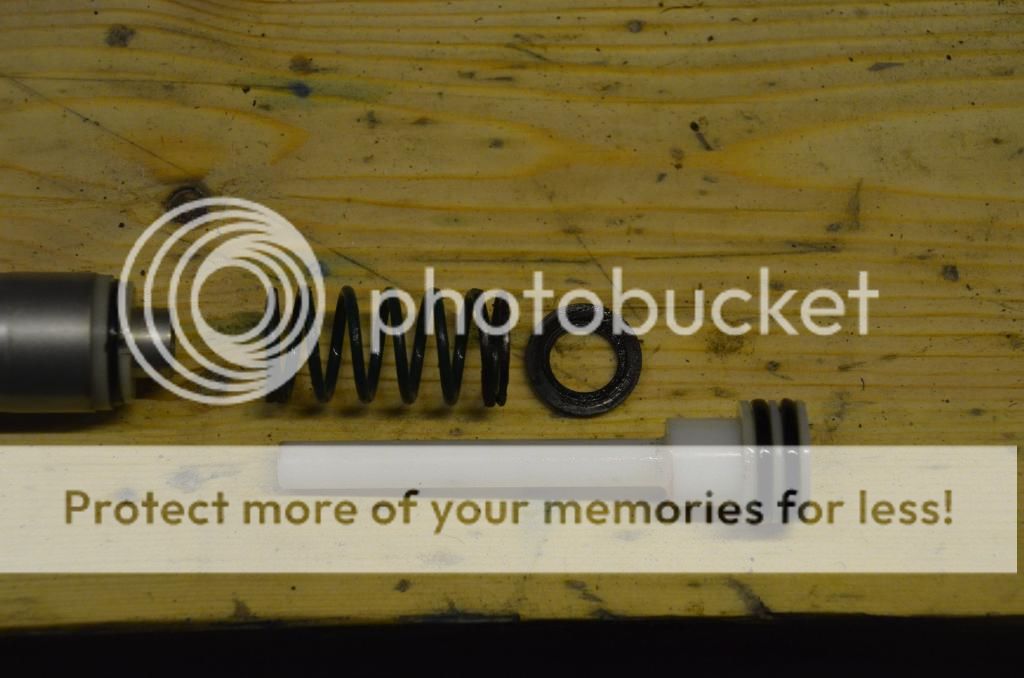

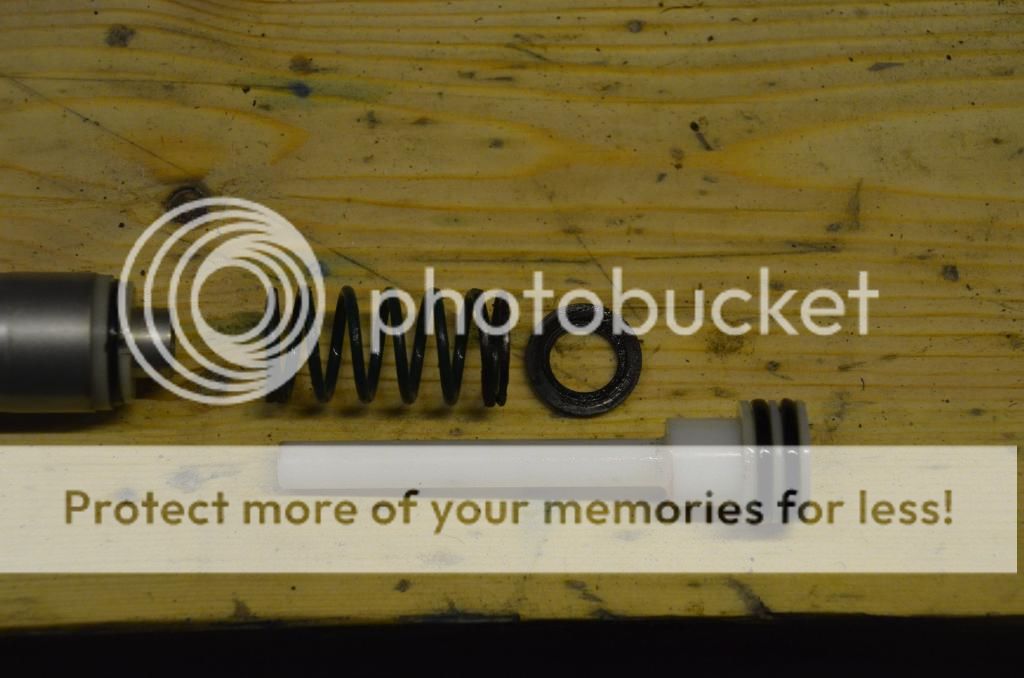

Air piston and return spring removed shown below

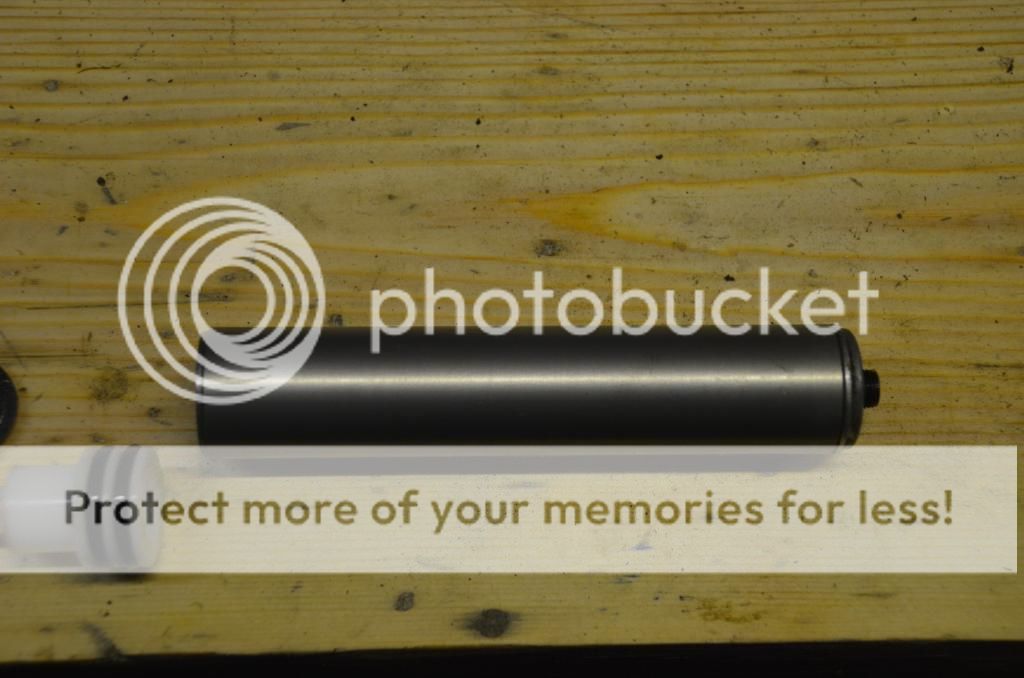

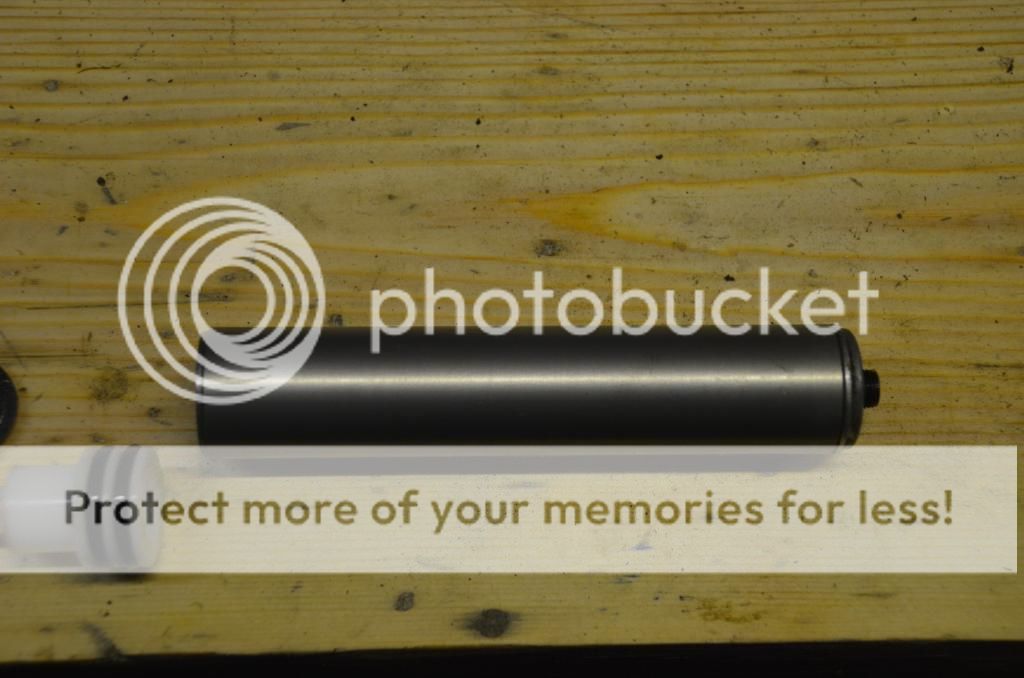

On one set of forks the air cylinder came out and the other it stayed put. I don't think there is any benefit in removing it. Below is what it looks like.

Once removed I drained the oil out of the damper and used the pin spanner to take the oil damper apart. In both instances I replaced the top and bottom piston seals. The bottom seals are the ones that wear out first and are often all that needs to be replaced.

Below is what the bottom seal looks like removed.

To get the bottom seals back with out the risk of damaging them I used the bullet tool and red grease. Got the grease from Ebay great stuff which helps to lubricate the seals until the oils works its way back into them. Bullet tool on the end of the shaft below

I don't have any images of how I replaced the top seals. I had access to a brake press. Used the shaft clamps to hold the shaft and pressed the centre rod out of the shaft. I will go into more detail at a later date when I get a chance.

Once I had replaced all the seals I filled the damper up with oil and moved it up and down to work the oil into both sides of the damper. Then to bleed it close the top nylon cap turned it upside down and then opened up the bleed screw inside the damper shaft. It took a few goes and eventually there was less noise inside when you moved the piston up and down. Then gave it a final top up oil to replace the space the air had taken up.

When finished there a thin film of oil on the shaft each time it goes up and down this is apparently normal.

Bruce

Both sets of forks below have the same DL80 oil and air damper inside them. The only difference between them is the one on the left doesn't have "V" brake mounts.

The tools I used are shown below

Pin spanner

Supercastle tool KT31

Red grease

Replacement seal kit HD166 (£3.99)

Fork oil 5WL

Bullet tool FT70

Shaft Clamps HDTL187

To remove the top cap I used a pin spanner to screw the cap off. (Please note leave the aluminium nut well alone. The aluminium nut is press fitted onto a spindle and if you rotate it with a spanner you could ruin it)

Once the top cap was removed below is the view inside. Then I let all the air out of the air piston and used the super castle tool to remove the cartridge.

Below is the supercastle tool in use. It takes a 3/8" socket wrench in the square hole in the top.

Once removed the oil damper is shown below

The air piston was still in the air damper I removed this by putting my hand over the top of the fork and putting a bit air into the damper and the piston shoots out. First time I did this it hit me in the face along with all the fork oil that had drained into the air cylinder - so be careful. There was also a return spring above the air piston.

Air piston and return spring removed shown below

On one set of forks the air cylinder came out and the other it stayed put. I don't think there is any benefit in removing it. Below is what it looks like.

Once removed I drained the oil out of the damper and used the pin spanner to take the oil damper apart. In both instances I replaced the top and bottom piston seals. The bottom seals are the ones that wear out first and are often all that needs to be replaced.

Below is what the bottom seal looks like removed.

To get the bottom seals back with out the risk of damaging them I used the bullet tool and red grease. Got the grease from Ebay great stuff which helps to lubricate the seals until the oils works its way back into them. Bullet tool on the end of the shaft below

I don't have any images of how I replaced the top seals. I had access to a brake press. Used the shaft clamps to hold the shaft and pressed the centre rod out of the shaft. I will go into more detail at a later date when I get a chance.

Once I had replaced all the seals I filled the damper up with oil and moved it up and down to work the oil into both sides of the damper. Then to bleed it close the top nylon cap turned it upside down and then opened up the bleed screw inside the damper shaft. It took a few goes and eventually there was less noise inside when you moved the piston up and down. Then gave it a final top up oil to replace the space the air had taken up.

When finished there a thin film of oil on the shaft each time it goes up and down this is apparently normal.

Bruce