As a thank you for 20 years of putting up with me and my incessant questions ,I've made a little gift for my LBS mechanic W.Bain

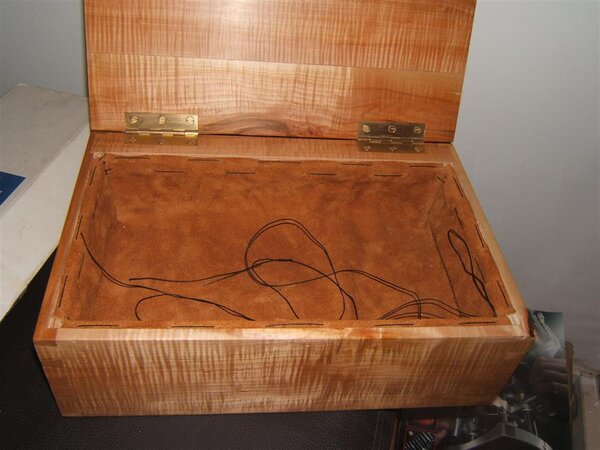

Its a wooden box

Its special in that it was made entirely by hand

But you would have had to saw some of it up i hear you say :? Thats how wood is converted from trees.

Not this time

This time it was done using a felling axe, then split using a hammer and wedges. Then split into quartered segments which in turn were hand worked flat using a scrub bladed plane(convex blade)(no4) then a fore plane(no6) then a smoothing plane(no4 1/2)

After many weeks work id produced a small box.

To put things in perspective- Using modern methods and machinery id have produced the same box in 3 days including all drying times and finishes applied.

This took 2 weeks possibly 3 just to produce the 8 small planks i would need and a further 3 weeks to put it all together.

To line the box i decided to make a leather bag that i would then secure to the inside. Finally deciding on 'stitching' it into and through the timber itself.

My initial choice of a bulls scrotum proved difficult to obtain as im not longer in that trade and the abattoir is long shut and everyone i knew long retired.

This choice would have allowed for a seamless bag and i think would have fitted together with the hand worked timber :?

A company called Trakke who i work in the same building as offered to make a leather bag for me .............if i make them something in payment .Like for Like

The owner showed me some bits on a site and liked a wooden spoon so i agreed to make him one.

Decided to use veneers to create a laminated construction.

It allows me to shape it and also add decorative detail in the form of other coloured timbers added in. Because its something that will then be sanded to shape it means there other colours can be shown trough in curves etc

Tricky as hell in that my experience of laminating is for large sections, doors, curved bases, which are glued up and clamped using air pressure in a huge vacuum bag. This isnt possible here so would need lots of small clamps applying pressure evenly around it but that in itself is problematic because A there isnt room and B it just doesnt work like that :?

A prototype was made and it came out rather well in mahogany laminate with an mdf core.

I produced the spoon bit first ,made from 2x 4mm thick quarter sawn oak with a 1.5mm African Blackwood veneer sandwiched in between. This meant when i started to carve in to produce the concave shape it would cut through to the blackwood then through that down to the oak and make a nice black ring.

The handle veneers are a mixture of mahogany straight grain for strength and cross grained maple for colour and included 6 veneers of Burr madrone(fing expensive £90/m) On the outside and base.

From the pics you should be able to make out the separate veneers in the spoon and the laminate veneers for the handle

As i thought the gluing up was a nightmare. not enough room for all the clamps and issues in that applying one clamp lessened the pressure elsewhere,especially on the the layers going around the curves

Personally i hate it

It hasnt turned out as well as i wanted. The handle looks way too long and i can see the problems caused by the poor clamping. Really difficult to sand and clean up.

As i think it a disappointment , i feel im letting the chaps making the bag down so thought id do him something ive a bit more practice in with a nice turned bowl in solid Japanese Maple(Rock Maple)

3 boards of 30mm glued together with a single sheet of exceptional quality mahogany veneer placed between each one

This mahogany came from Andrew Gardener Cabinetmakers(Shut down) They did 5star hotel quality for the likes of Japan and the middle east and is the best you can get.

Finished box pic- Fiddleback Ash. Riven on the quarter with varying sizes dovetails.

Spoon pic- Oak/Blackwood Spoon with burr Madrone laminated handle

Bowl pic - Japanese hard maple with Hondurans Mahogany bands