My new city hack  :

:

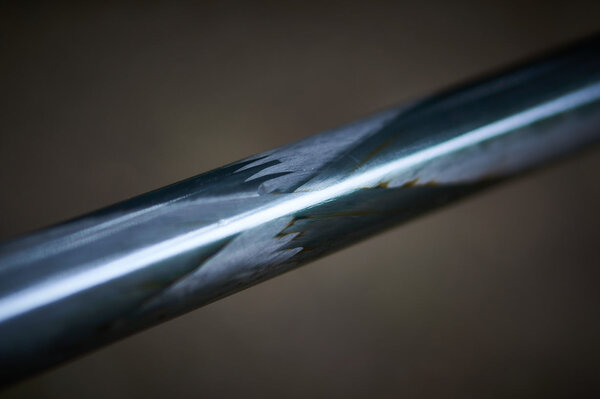

I finally managed to get together all the bits for my Vitus FCK9 singlespeed conversion, and I reckon its gone pretty well! The chain is a little crackly sometimes, which I guess is a tension/alignment issue. One that I'll have to live with when the dropouts are almost vertical... Unless i get one of those ugly tensioners :?

Total cost of the build was about £250 (a fair few of the parts came from free donor bikes)

Full details are below, what do people think?

Frame: Vitus FCK9 Carbon Kevlar

Fork: Schwinn Alloy

Headset: Tange Seiki Threaded 30.3mm Stack

Stem: SunRace Quill

Handlebar: Tange Road Champion

Bar Tape: Velox Cotton Red

Brake Levers/Brifters: Shimano 600

Brake Calipers: Shimano 105

Brake Pads: Shimano 105

Brake Cables: Jagwire Braided

Cassette: 14T

Chain: Gusset Slink Half-link Red

Cranks: SunRace 50T/30T Double

Pedals: Wellgo M142

Wheelset: Shimano Ultegra WH-6500

Tyres: Schwalbe Lugano 700x23C Red Stripe

Tubes: Continental Race 28

Saddle: Kona Race

Seatpost: Peugeot 23.0mm

Extras: Knog Strongman Lock/Bracket

Weight: 8.5KG (Excl. lock)

I finally managed to get together all the bits for my Vitus FCK9 singlespeed conversion, and I reckon its gone pretty well! The chain is a little crackly sometimes, which I guess is a tension/alignment issue. One that I'll have to live with when the dropouts are almost vertical... Unless i get one of those ugly tensioners :?

Total cost of the build was about £250 (a fair few of the parts came from free donor bikes)

Full details are below, what do people think?

Frame: Vitus FCK9 Carbon Kevlar

Fork: Schwinn Alloy

Headset: Tange Seiki Threaded 30.3mm Stack

Stem: SunRace Quill

Handlebar: Tange Road Champion

Bar Tape: Velox Cotton Red

Brake Levers/Brifters: Shimano 600

Brake Calipers: Shimano 105

Brake Pads: Shimano 105

Brake Cables: Jagwire Braided

Cassette: 14T

Chain: Gusset Slink Half-link Red

Cranks: SunRace 50T/30T Double

Pedals: Wellgo M142

Wheelset: Shimano Ultegra WH-6500

Tyres: Schwalbe Lugano 700x23C Red Stripe

Tubes: Continental Race 28

Saddle: Kona Race

Seatpost: Peugeot 23.0mm

Extras: Knog Strongman Lock/Bracket

Weight: 8.5KG (Excl. lock)