Captain Stupido

Senior Retro Guru

- Feedback

- View

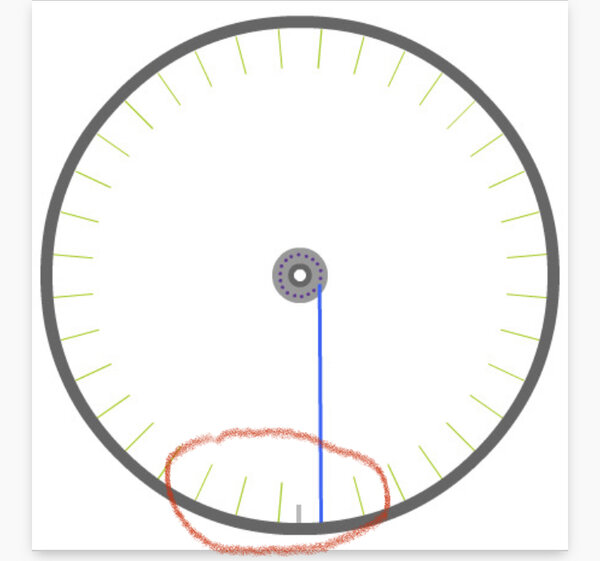

Going a bit mad here trying to get started on a wheel build. Got some old DX hubs, new rims, spokes and nipples.

I was using the Sheldon Brown site as a guide.

Sheldon says:

“The key spoke will be a trailing spoke, freewheel side....Since the key spoke is a trailing spoke, it should run along the inside of the flange. The head of the spoke will be on the outside of the flange.“

Looking at my old hub, the wear from the old spokes indicates that the spokes were installed the other way round. I.e. leading spokes ran along the inside of the flange on the drive side (and on the outside on the left side, so it makes no difference which way round the up hub goes).

I then had a look at some other ready build bike wheels and they don’t conform to a standard, all are laced differently, some have both leading spokes on the outside, some are have leading spokes both left, some have both right.

I googled for another guide. https://patricktaylor.com/building-a-bicycle-wheel looked good... he says:

“Leading spokes point from the flange in the direction of rotation of the wheel. The first leading spoke to be fitted is known as the key spoke. It comes out of the flange on the outside” (on the right hand side of the wheel)

So again, different from the previous lacing pattern on my hub, and to confuse matters he chooses a different spoke from Sheldon as the key spoke.

What should I do? Follow the wear pattern on the hub on the basis that the flanges are less likely to fracture, or start again using Sheldon’s advice?

I was using the Sheldon Brown site as a guide.

Sheldon says:

“The key spoke will be a trailing spoke, freewheel side....Since the key spoke is a trailing spoke, it should run along the inside of the flange. The head of the spoke will be on the outside of the flange.“

Looking at my old hub, the wear from the old spokes indicates that the spokes were installed the other way round. I.e. leading spokes ran along the inside of the flange on the drive side (and on the outside on the left side, so it makes no difference which way round the up hub goes).

I then had a look at some other ready build bike wheels and they don’t conform to a standard, all are laced differently, some have both leading spokes on the outside, some are have leading spokes both left, some have both right.

I googled for another guide. https://patricktaylor.com/building-a-bicycle-wheel looked good... he says:

“Leading spokes point from the flange in the direction of rotation of the wheel. The first leading spoke to be fitted is known as the key spoke. It comes out of the flange on the outside” (on the right hand side of the wheel)

So again, different from the previous lacing pattern on my hub, and to confuse matters he chooses a different spoke from Sheldon as the key spoke.

What should I do? Follow the wear pattern on the hub on the basis that the flanges are less likely to fracture, or start again using Sheldon’s advice?