Joe*Pro

Senior Retro Guru

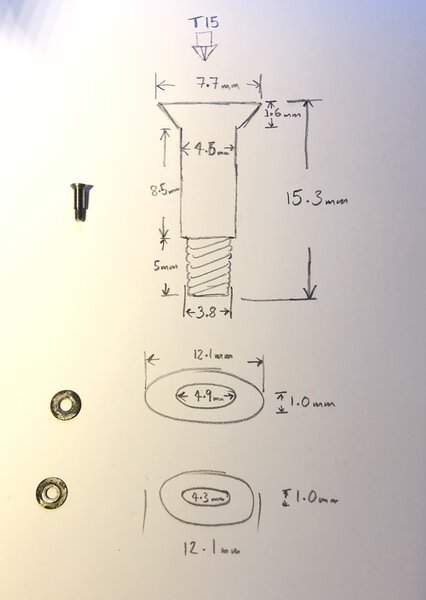

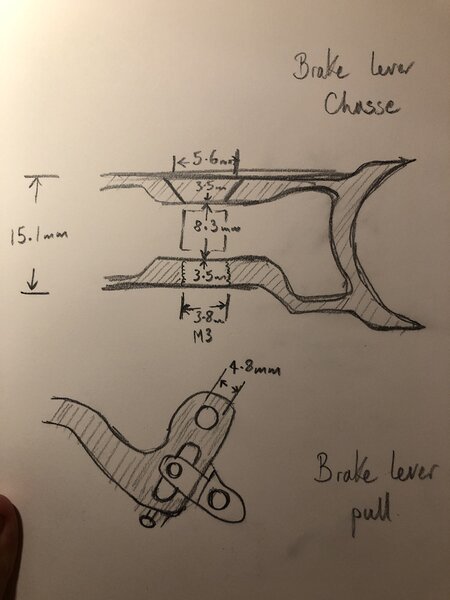

See dimensions of this shoulder bolt below. The 2 washers are then 1mm thick and upper one has 4.9mm hole, the other lower one has 4.3mm hole to sit on the base of the shoulder, over the thread. They are both 12mm outer diameter, but aslong as it covers the lever arm hole and inner bearing think outer diameter just needs to be 10mm or so.

The only similar bolt I can find is that M3 traditional head. But I don’t have a lathe. Wondering if I can tighten it in my drill chuck to spin it to file it down to a counter sunk version.

The only similar bolt I can find is that M3 traditional head. But I don’t have a lathe. Wondering if I can tighten it in my drill chuck to spin it to file it down to a counter sunk version.

Attachments

Last edited: