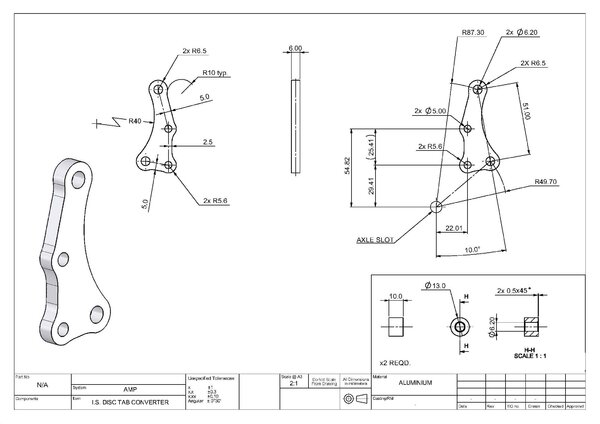

AMP disc converter

Hello.

It was me who was selling the AMP forks with the adapter.

I am sorry to whoever said I took forever to reply to their email. I only use this site whenever I have something to sell or need to buy, which is rarely. I think that's fair enough isn't it?

I designed the bracket from the tech drawings that came straight from AMP in the States. If you contact them, they can send you tech drawings for the AMP fork brackets, the rear brackets, and their disc brake schematics. They could, if willing, also send you my CAD drawing which is fully dim'ed up as I sent it to them as a return of favour for them providing me with their drawings, for distribution to anyone else who was trying to do the same as me (i.e: you lot). I take no responsibility for failures either of the design or of the part though, I am not a component manufacturer.

From what I can see from the CAD plot above, looks like the thinking is correct. I'd make in alu plate and mount the adapter on the OUTSIDE of the AMP tabs and use spacers to bring the caliper back INWARDS towards the hub centre, otherwise you'll either need to use a flimsy bit of steel for the plate or you'll need to machine in a step to bring the plate back out to the plane of the AMP tabs.

My design is made to be CNC milled or wired out, then holes drilled, then anodised. Don't forget to anodise. As someone else here said, if you turned these brackets out in small batches in the UK, you'd need to be selling them for £50 upwards just to make it worth your while, so i thought my asking price with the forks was very reasonable.

I would post the drawings here but they're on my work PC and its Saturday. Email Brion at AMP and they'll sort you out a set of PDFs of my design. You can get IS dims by googling 'IRD dual banger mechanical brakes' and look for the PDF manual. Theres a diagram on there.

You can email me at

andrewwolfenden@googlemail.com if you need a quicker response.

Hope this helps. PS can someone who knows this site better than me please post a link to my 'for sale' thread? There are some good reference pics of my adapter there. Ta.