Blackbike

Retro Guru

I bought a new Rennkompressor pump and found it very well built, I liked the all steel construction and the cast iron base. Nice details are the wooden pump handle and folding feet. Its very old school and the weight is substantial, as it should be. Pumping action is nice an easy to 150 psi (tested with a closed presta valve), PSI range on my tires is from 80 PSI to 120 PSI on the bikes that I own, and the pump is perfect within my pressure range. The claimed maximum pressure for this pump is 240 PSI.

Things I did not like, first is the pressure gage.

The gage face is black and the PSI increments are every 10 PSI, so good luck trying to set your tire pressures accurately. The psi scale is gray in color and invisible when in use, the diameter of the gage is 2 inches and the protective plastic cover casts a shadow over over the gage face when the lighting isn't perfect. The gage itself has a plastic case.

Second the hose connection to the cast iron base.

The hose connection to the pump base is a straight thread connection sealed with an o-ring, good in theory but the hose connection fitting does not make contact with the base, it sits on top of the o-ring and cannot be tightened enough to keep the fitting from unscrewing from the pump base if there is a twist in the hose when the hose is pressurized :facepalm: . A drop of loctite would fix this.

Third the supplied pump head.

The EVA pump head is a big lump of plastic that works ok, but feels flexy when the locking lever is used and it's really big for what it does.

None of this is that big of a deal and most of it is personal preference at best or minorly annoying at worst, BUT IT MAKES ME NUTS. So let's fix it :shock: .

This is a standard SKS Rennkompressor...

This is my Rennkompressor after modification.

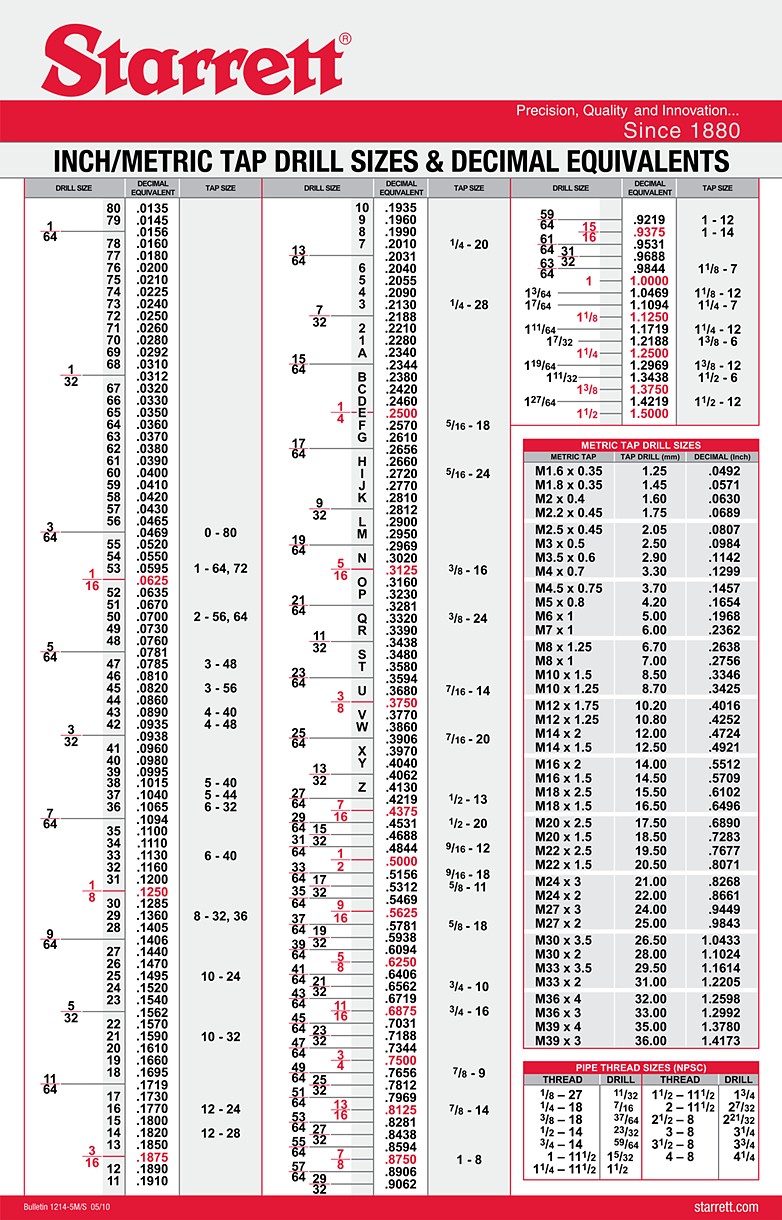

The gage replacement required recutting the threads in the pump base using 1/4 NPT tapered pipe tap to accept a standard industrial 160 PSI gage, the existing gage used an ISO straight pipe thread, no drilling required just run the tap in to convert to NPT. The replacement gage is a 2 1/2" WIKA glycerine filled 160 PSI process gage P/N 9767223.

The newly installed gage that you can actually read.

Next up was fixing the very annoying hose that kept loosening. This modification required drilling the hose port using a "Q" drill so it could be tapped to 1/8 NPT tapered pipe threads so it would accept a standard 1/8" NPT to 1/4" hose barb, as the supplied SKS fitting won't accept standard 1/4" air hose :facepalm: . The hose used was 1/4" 300 PSI rated industrial air hose, the fitting is a SSP 300 PSI rated hose barb, and the hose clamps are Oetiker.

The new hose fitting and hose installed.

The only thing left was to install the Kuwahara Hirame pump head which is an absolute joy to use and feels great in the hand.

The new pump head installed, with the EVA head for comparison.

Other minor stuff done was dissassembly and cleaning of the entire pump to remove the chips from cutting the threads, and to remove the factory grease prior to replacement with Dupont Krytox teflon grease, the thread sealant used was Loctite 569 Hydraulic thread sealant, and the air hose is retained by a trimmed toe strap.

This is a quality pump with old school construction that makes it very easy to upgrade or repair, I chose this pump for myself as I was looking for a tool, not an art object. It is well worth the price. I would recommend the SKS to anyone looking for a high pressure track pump

Best Wishes: Mike

Things I did not like, first is the pressure gage.

The gage face is black and the PSI increments are every 10 PSI, so good luck trying to set your tire pressures accurately. The psi scale is gray in color and invisible when in use, the diameter of the gage is 2 inches and the protective plastic cover casts a shadow over over the gage face when the lighting isn't perfect. The gage itself has a plastic case.

Second the hose connection to the cast iron base.

The hose connection to the pump base is a straight thread connection sealed with an o-ring, good in theory but the hose connection fitting does not make contact with the base, it sits on top of the o-ring and cannot be tightened enough to keep the fitting from unscrewing from the pump base if there is a twist in the hose when the hose is pressurized :facepalm: . A drop of loctite would fix this.

Third the supplied pump head.

The EVA pump head is a big lump of plastic that works ok, but feels flexy when the locking lever is used and it's really big for what it does.

None of this is that big of a deal and most of it is personal preference at best or minorly annoying at worst, BUT IT MAKES ME NUTS. So let's fix it :shock: .

This is a standard SKS Rennkompressor...

This is my Rennkompressor after modification.

The gage replacement required recutting the threads in the pump base using 1/4 NPT tapered pipe tap to accept a standard industrial 160 PSI gage, the existing gage used an ISO straight pipe thread, no drilling required just run the tap in to convert to NPT. The replacement gage is a 2 1/2" WIKA glycerine filled 160 PSI process gage P/N 9767223.

The newly installed gage that you can actually read.

Next up was fixing the very annoying hose that kept loosening. This modification required drilling the hose port using a "Q" drill so it could be tapped to 1/8 NPT tapered pipe threads so it would accept a standard 1/8" NPT to 1/4" hose barb, as the supplied SKS fitting won't accept standard 1/4" air hose :facepalm: . The hose used was 1/4" 300 PSI rated industrial air hose, the fitting is a SSP 300 PSI rated hose barb, and the hose clamps are Oetiker.

The new hose fitting and hose installed.

The only thing left was to install the Kuwahara Hirame pump head which is an absolute joy to use and feels great in the hand.

The new pump head installed, with the EVA head for comparison.

Other minor stuff done was dissassembly and cleaning of the entire pump to remove the chips from cutting the threads, and to remove the factory grease prior to replacement with Dupont Krytox teflon grease, the thread sealant used was Loctite 569 Hydraulic thread sealant, and the air hose is retained by a trimmed toe strap.

This is a quality pump with old school construction that makes it very easy to upgrade or repair, I chose this pump for myself as I was looking for a tool, not an art object. It is well worth the price. I would recommend the SKS to anyone looking for a high pressure track pump

Best Wishes: Mike