Just a few ...

I think there are only the mechs that havent been on (but little I can do with them and we know what they look and fit like) and the new bars and stem

The anodising is back from Rampage - all good other than one bit which I expected not to be great as it was part corroded and then cleaned up before I sent it :

Best stuff on the left, spares in the middle and on the right.

The seat post bits and pulley covers are for the Airborne. The black round bits are Ringle Zooka bits that will go on the Yo.

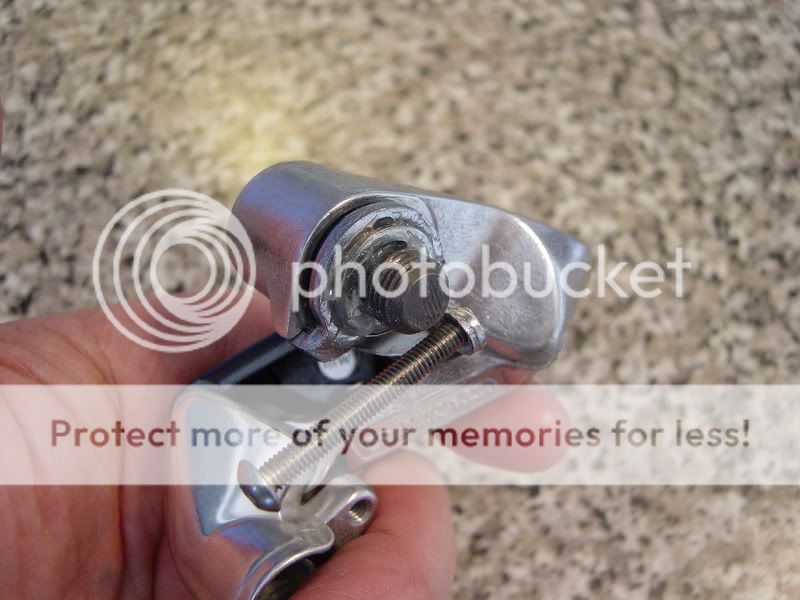

Ti rear mech bits for swapping out :

I had a second Ti / ceramic pulley but the 970 mech has a floating top pulley so I will leave that as is

The X Kings have been filled with stans. They sealed up quite well and are now holding air without dropping pressure 60ml in each, took two days and probably about eight lots of shaking each

60ml in each, took two days and probably about eight lots of shaking each

WD

I think there are only the mechs that havent been on (but little I can do with them and we know what they look and fit like) and the new bars and stem

The anodising is back from Rampage - all good other than one bit which I expected not to be great as it was part corroded and then cleaned up before I sent it :

Best stuff on the left, spares in the middle and on the right.

The seat post bits and pulley covers are for the Airborne. The black round bits are Ringle Zooka bits that will go on the Yo.

Ti rear mech bits for swapping out :

I had a second Ti / ceramic pulley but the 970 mech has a floating top pulley so I will leave that as is

The X Kings have been filled with stans. They sealed up quite well and are now holding air without dropping pressure

WD