You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1997 Amp Research B4 Mercedes Benz

- Thread starter trail_head

- Start date

trail_head

Retro Guru

Thank's guys! I've got a long way to go yet. I always appreciate your comments.

I did a bit more polishing tonight. I'm heading over to the machine shop tomorrow. I'll try to take some pictures to entertain you.

I did a bit more polishing tonight. I'm heading over to the machine shop tomorrow. I'll try to take some pictures to entertain you.

trail_head

Retro Guru

Kestonian":214h1z2t said:Very nice!

What's the serial number on yours?

I love the blue ... mine is silver.

Frame # f9910. It left Amp in Feb '97

trail_head

Retro Guru

Fresh back from a successful 2.5hrs at the machine shop. I did this at the Best Bikes shop under the watchful eye of Mr Best himself. It's so fun to be practicing machine skillz while building pimpass partz for my ride!

First up was the Bar ends;

Finished;

Going in reverse order;

First up was the Bar ends;

Finished;

Going in reverse order;

trail_head

Retro Guru

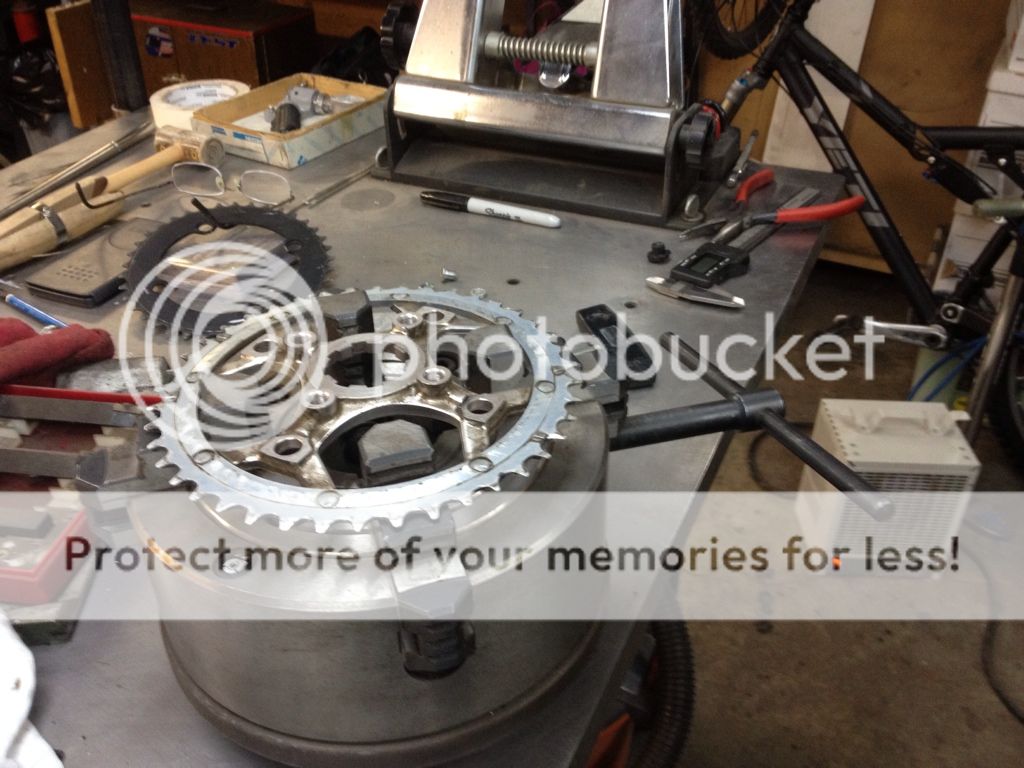

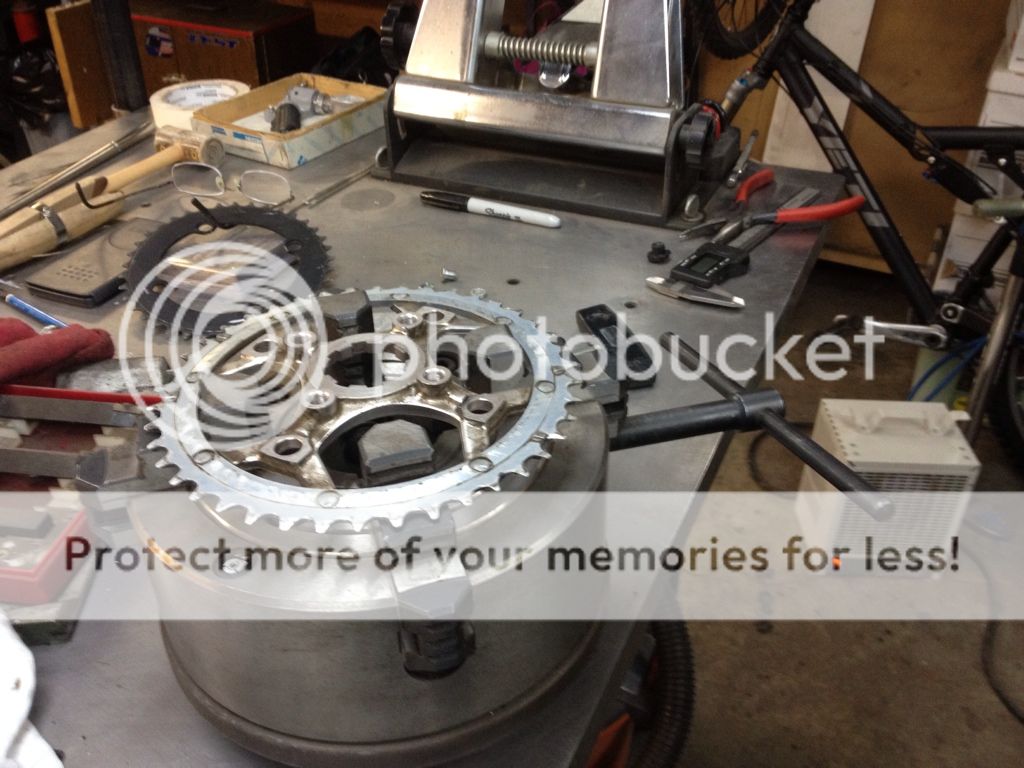

To machine mate the m739 spider to the M950 arm requires some surfacing of the clamped area at the center. On this frame there's enough room to move the chainline inboard about 3.mm. The offest difference between these and the m950 spider is about 2.5mm so this means I was able to machine the back side of the spider thus lowering my effective chainline to about 47.5mm.

Setting up in the 4-jaw chuck;

Switching the chucks;

I'll post more on these last two bits after they're cleaned and installed.

Setting up in the 4-jaw chuck;

Switching the chucks;

I'll post more on these last two bits after they're cleaned and installed.

trail_head

Retro Guru

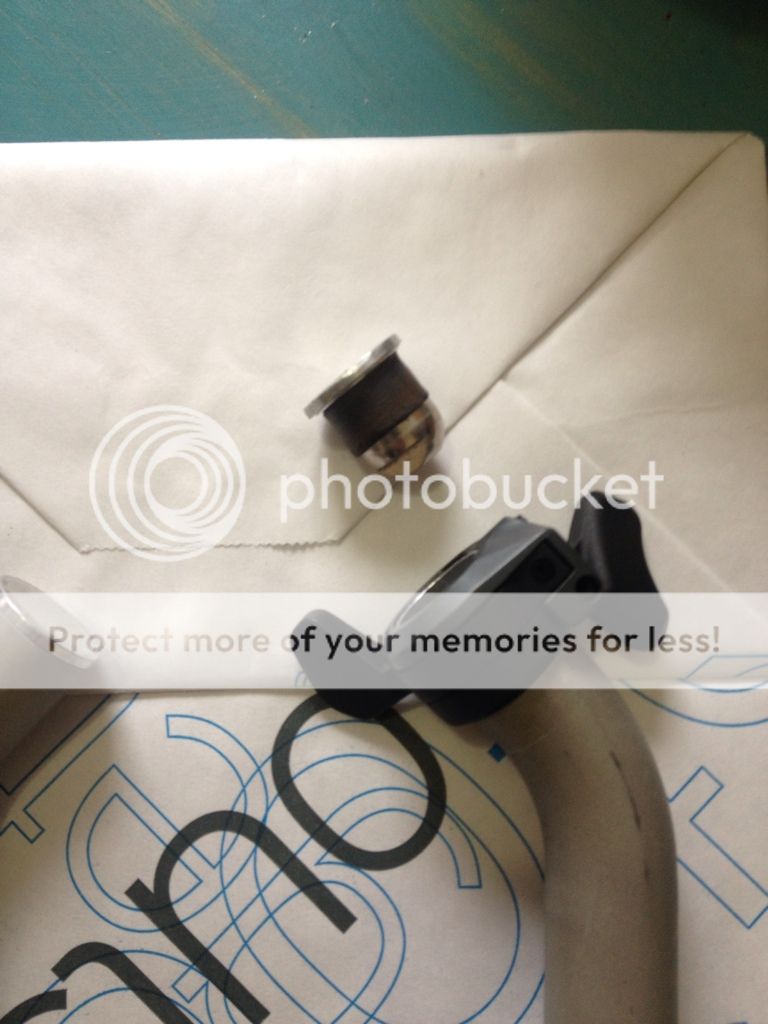

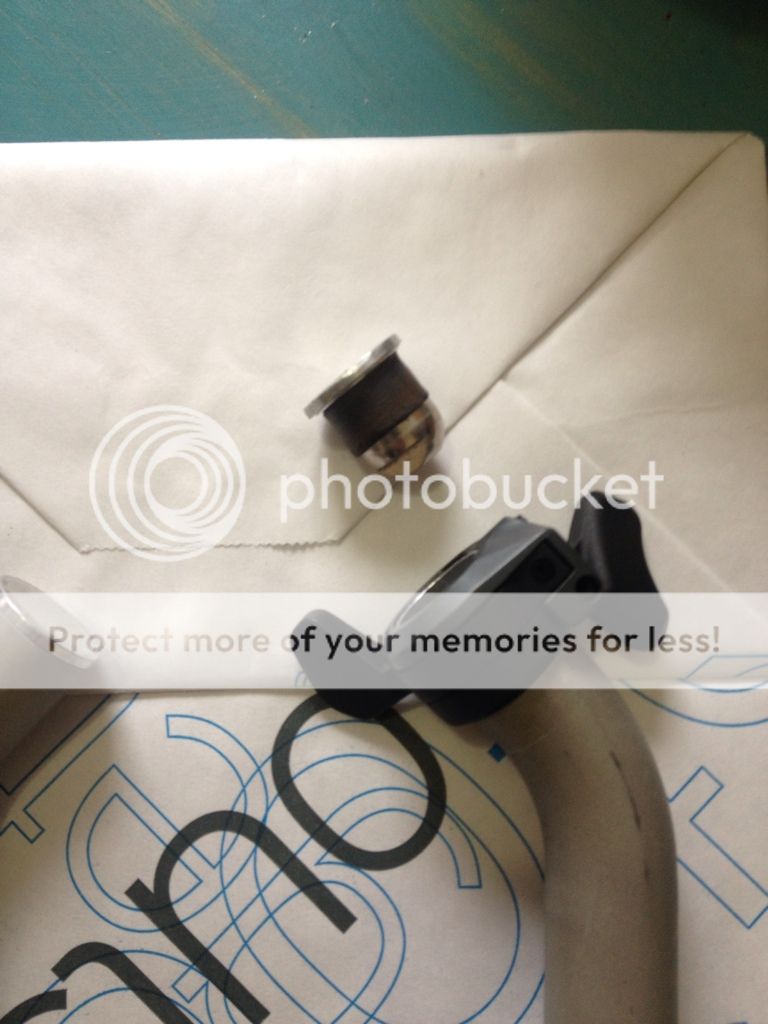

I forgot to show how I made the bar end cap removable on the last posts.

I bonded a 5mm aluminum bolt to the inside of the cap and used a rubber expansion block from an old bar plug with an aluminum Q/R nut.

I'm very happy with the finished product on these

I bonded a 5mm aluminum bolt to the inside of the cap and used a rubber expansion block from an old bar plug with an aluminum Q/R nut.

I'm very happy with the finished product on these

Similar threads

- Replies

- 12

- Views

- 928

- Replies

- 11

- Views

- 2K