I've had the black fingers recently too.. You two obviously got more stamina for it than me, though..

Regarding your front dropouts...

As with most things in life, the actual procedures are fairly simple and quickly described...It's all the caveats involved that need carefully considering. Providing yourself with the best possible 'anchor', and the most favourable leverage situation, is a good foundation for success, in mechanickin', and doubtless elsewhere. Also, with vices, hammers, files, etc., start gently and tentatively.. maximum force is rarely necessary or desirable. I'm not assuming anyone is an idiot, but it can be helpful to all of us if someone restates the obvious now and then. Also I hope I don't come across as some patronising bike know-it-all... I have as much to learn as anyone. Let me say right now that I have NEVER DONE THIS. I'm just sharing my thoughts on what to do about it, in the spirit of "two heads are better than one", and in the absence of the framebuilder's dropout-alignment equipment. If anybody thinks my suggestions are foolhardy or irresponsible they should say so. I don't want anyone breaking shit and blaming it on me.

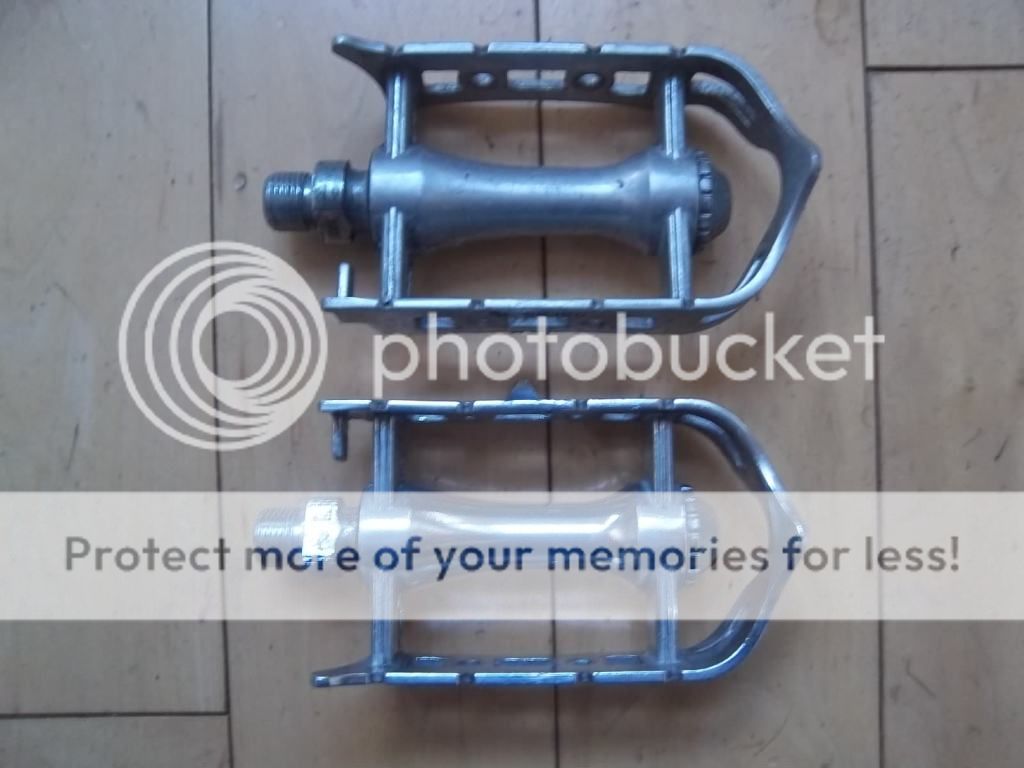

It would be helpful to have an unencumbered front-axle on hand. Trying to fit the axle into the dropout will give you a good idea where the problem is.

I assume that thanks to LBS you now have headset and forks fitted. You could do what I am about to describe with the frameset thus assembled, but you would have to support the weight of the frame while doing it. Frames without wheels are easily distorted, and the last thing you want is the whole weight of your frame anchored by one front dropout. That would be a BAD leverage situation! For that reason it would be better to remove the forks from the frame. (Easy for me to say!) Either way, don't put yourself in a situation in which you, or anyone else, is likely to bump into your frame/forks while they are secured in the vice by one dropout. (This is for your forks' sake, clumsy organisms can shift for themselves!)

I know I've said this before, but if you can get hold of the by now presumably almost obsolete "3 big spanners", removing (and replacing) your forks is easy. LBS have pressed your crown-race, bottom cup, and top-race home, and they can stay there. Removing the forks is just removing the locknut and spacer, unscrewing the top cup, and pulling the forks out.

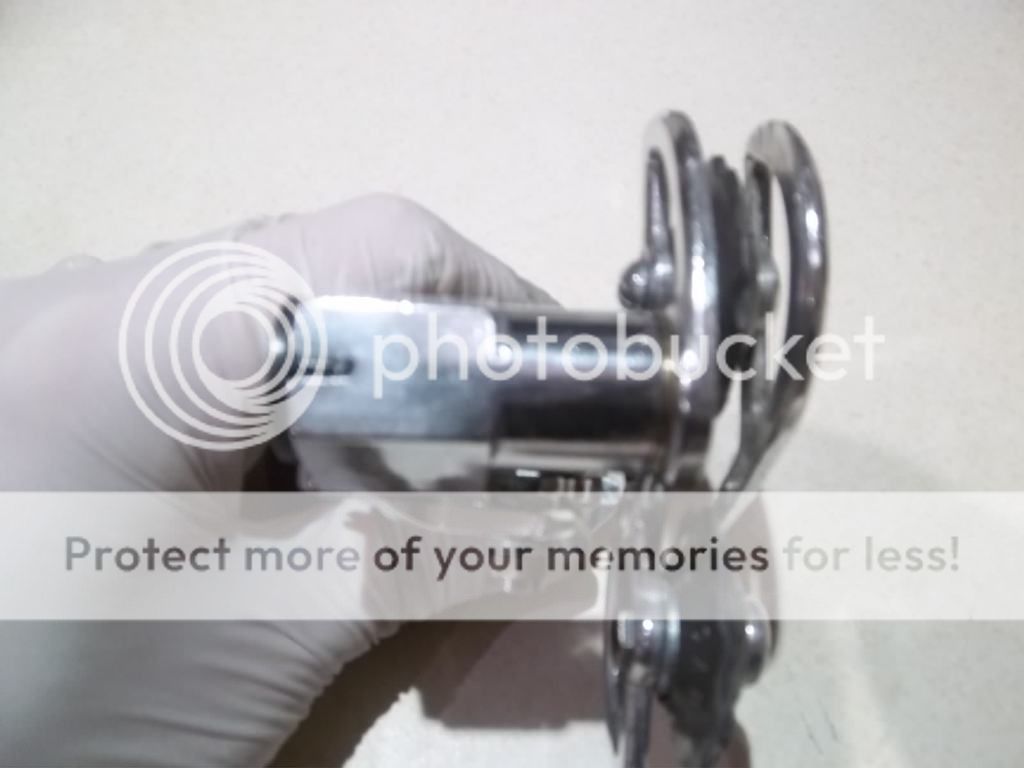

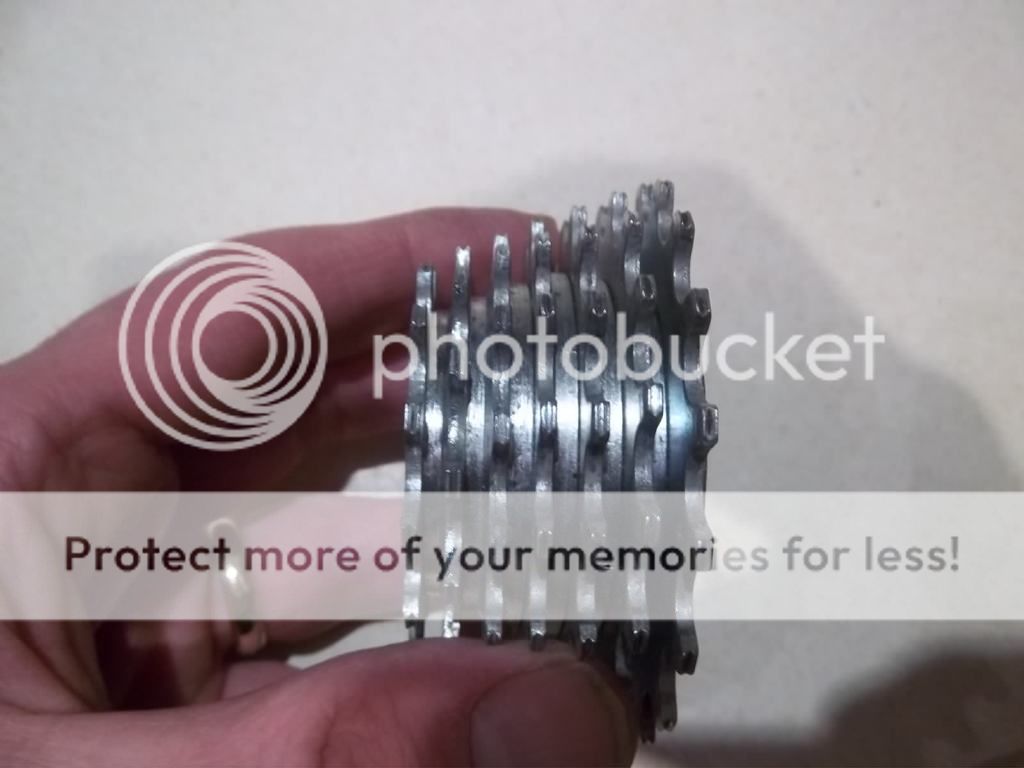

Either way, what I would do is to secure each front dropout in turn in a vice, thus

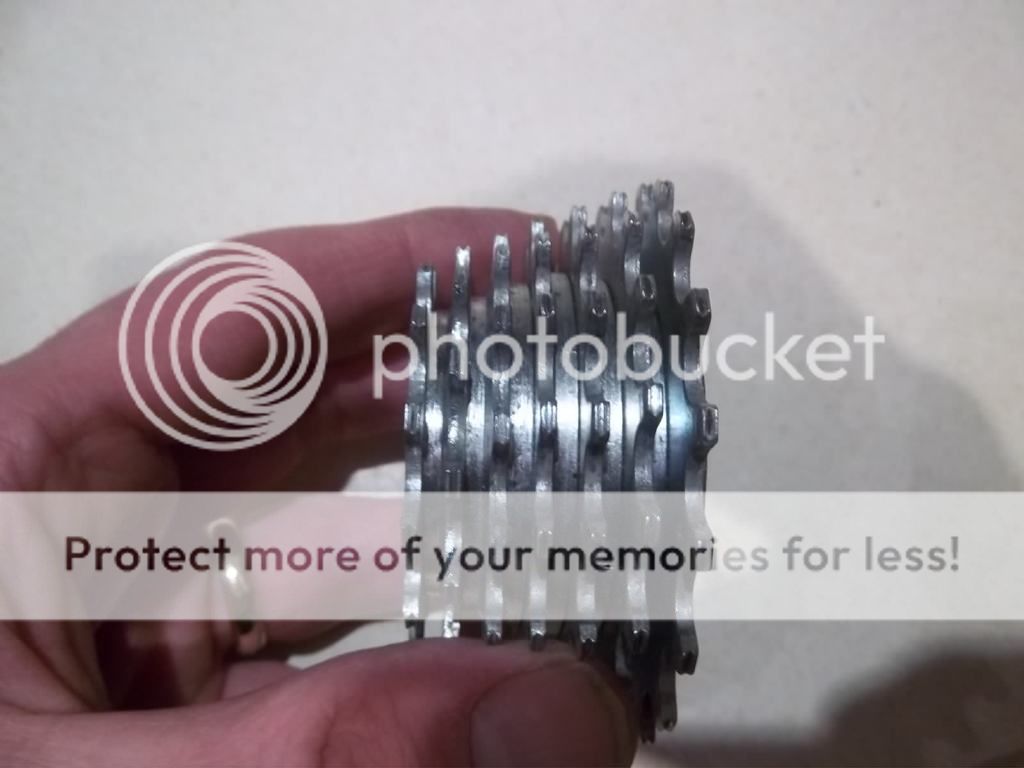

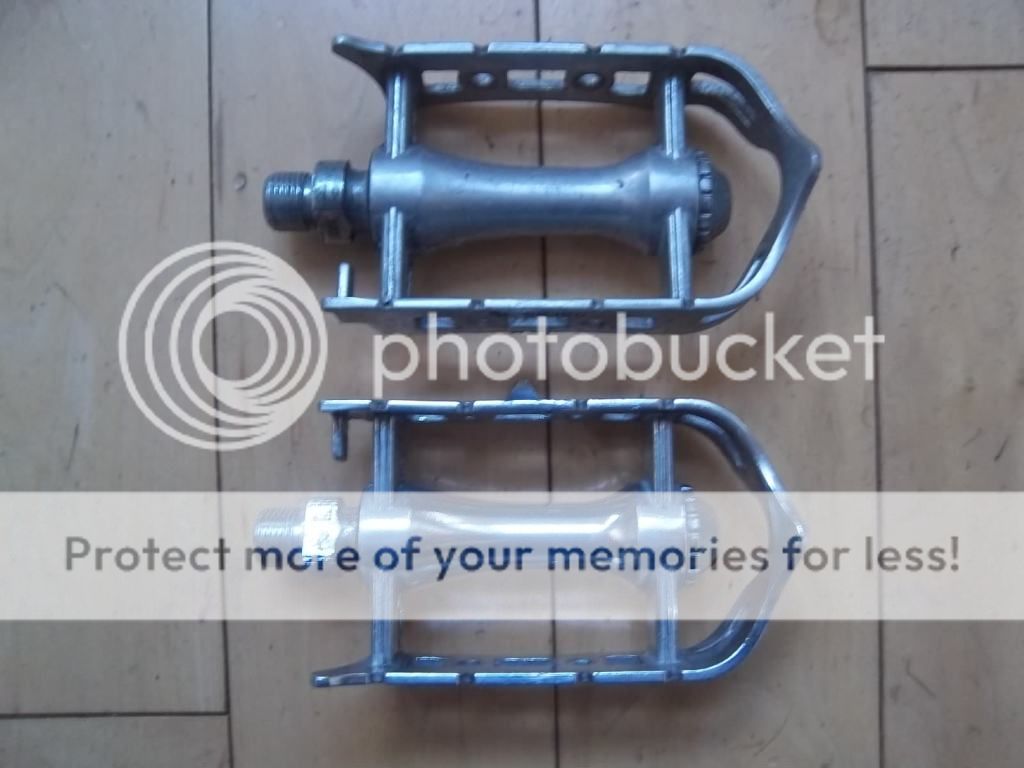

and give it a good strong squeeze... but be careful not to bend sideways the "neck" of the dropout, where it joins the fork blade, while you are doing this, (or at any other time during this whole procedure). Once you have done that, secure each dropout in turn in the vice, thus,

and try the axle. If it gets "trapped", you need to judiciously file the opening until the axle can slide past. Don't file the "curve" where the axle should sit, just the front side of the "corridor" that leads to it; i.e. the part facing upwards in the vice, in the picture. Once the axle can slide home fully into both dropouts, your work is done, and you can reassemble.

I have favoured filing over bending (back), because we know what happens when metal is bent back and forth..