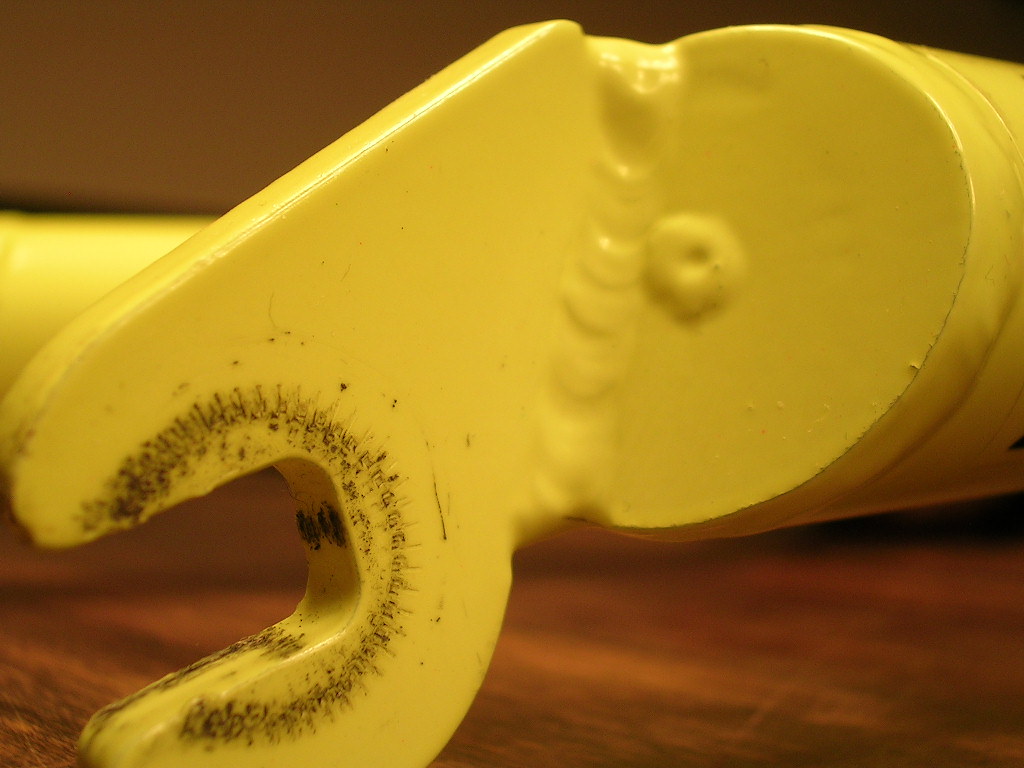

whoa, seeing that pic of the cap with no hole gave me shivers. That is a really old one, from the bikes made in San Fernando or Burbank. When I started welding the forks, I was gradually allowed to make subtle changes (as mentioned) Among those, was using a vent hole. Since John lived near the beach and salty air, he wanted the frames "sealed". I was welding fast enough to need an additional vent hole (later to be filled). Dare I say it might pre-date FTW?

Funny story: Before I worked for Yeti, I was a BMX production welder for Mongoose (actually a contractor C&L welding.) and was welding over 150 forks a day with no problem. I was getting paid $1.50 each and making very good money for the day. I also worked in engineering and could design and build nice fixtures. Specially for forks.

When I first met John, who was making Yeti forks one at a time, I worked using his methods (NOT production friendly) for a couple of days and made a deal with him to make forks for $25.00 each (labor) With him thinking I could make one a day.. LOL. I was able to make 100 forks the next week and his bill was $2500 ! (perhaps 4-5 weeks wages for the average worker) I ended up making a deal and secure position with an awesome company for my efforts.