videojetman":s4flod4m said:how's the build going ?

looking forward to seeing this done.

Thanks for all the positive comments so far! - thanks for the scans too Dossa. Haven't got these but then you are an MBUK guru round these parts!!

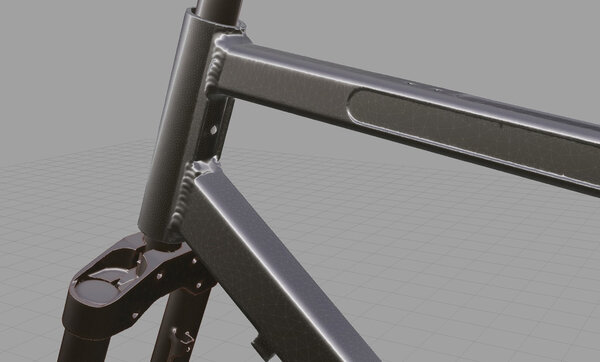

It's early days still at the moment VJM, but all of the thick powdercoat is now off!! ( at last!! ) and the fork legs, stem and Bullseye's will go into paint. Colour chosen - Metallic yellow Glazurit MY005.55

Silver as yet undecided as the fork crown is not back from the anodiser yet. Looking to get this in the RC100S spec colour rather than the normal black - then match the silver to suit.

Graphic proof has been sent to www.digiwrapltd.co.uk after recommendation from a friend...

Scored the all important yellow toes straps too - result.

Expect slow progress in the coming weeks.

Cheers

boy"