You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Funk unicorn

- Thread starter Swede

- Start date

Re:

Seems just like Manitou to me, no?

Seems just like Manitou to me, no?

Re:

Yes, defo like my Manitou 3 forks.

Yes, defo like my Manitou 3 forks.

Re:

Have a look here:

http://www.retrobike.co.uk/gallery2/d/1 ... r+fork.pdf

Whilst that is for the rear of an FS frame, it's the same system principle as the III forks up front...

Have a look here:

http://www.retrobike.co.uk/gallery2/d/1 ... r+fork.pdf

Whilst that is for the rear of an FS frame, it's the same system principle as the III forks up front...

Smithjss70

BoTM Winner

- Feedback

- View

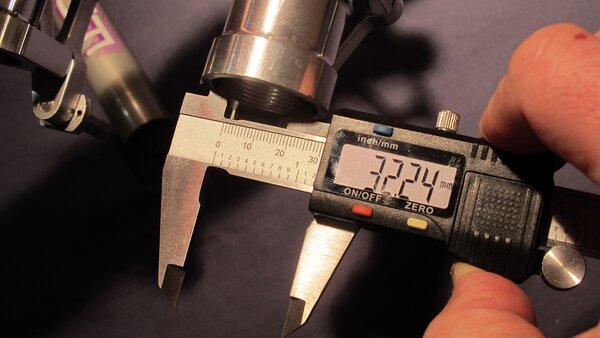

So the issue is the gap (0.5mm) between the stanchions and the caps? Would an o-ring solve the problem Caspar? Need a pic to better understand I guess.

Smithjss70

BoTM Winner

- Feedback

- View

I see. So that's a tough call since a potential and permanent solution may prohibit easy access to the internals long term. Do you plan on riding/using the fork? I assume so.

syncrosfan

Senior Retro Guru

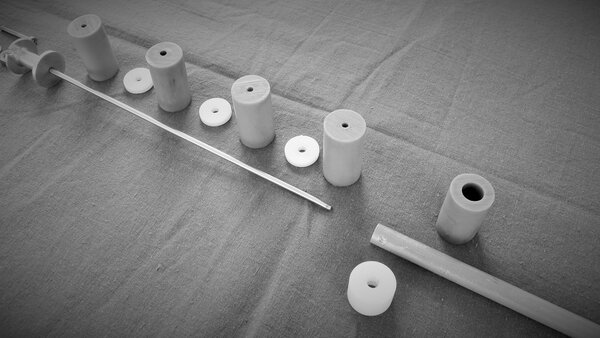

If you use a proper industrial strength epoxy adhesive the gap between the two parts makes sense. I would suggest "Loctite Hysol 9430" (has one the highest shear and peel strength off all the commercially available adhesives out there). This adhesive requires a ca. 0.25 mm radial gap between the two materials in order to form a proper bond-line. (look up bond line control) Sometimes you can mix tiny glass beads into the adhesive to insure an even bond line. That being said bonding into a threaded part seems... well... wonky. don't get it why they would have threaded the surface if those parts are supposed to be bonded but I guess it should still work. This particular adhesive is very viscous so it will fill up the threads. The down side: it's expensive (mainly because it doesn't come in small quantities).

Attachments

Similar threads

- Replies

- 77

- Views

- 9K

- Replies

- 34

- Views

- 2K

- Replies

- 48

- Views

- 5K

- Replies

- 15

- Views

- 973

Latest posts

-

-

New (old) Kona fire mountain

- Latest: NigelFinnighan

-

-

-