You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3d printed bike

- Thread starter tintin40

- Start date

Frame design is a bit yuck (to my eyes), but the concept is immense - particularly moving away from your traditional 3D printed stuff, which has always looked a little bit naff to me (although it may be I've not seen as much as I should have!) and into carbon fibre. Wow. Quality of the finish is amazing as well!

Interesting for the scale of the printer used, (which will be where the future money is coming from) but the problem he will have is the lack of compaction into, or onto, a mould (so a low carbon/resin ratio) and only a single plane for the fibres to be orientated.

Looks like the frame is printed laying on its side and hollow, with fibre layers horizontal, (vertical plane on the finished bike) so vertically stiff with just the thermoplastic resin handling sideways and bursting forces...very difficult to handle torsional forces, too.

The fibres are inevitably short, overlapping chopped fibre, compared to woven or non-woven carbon.

Often the physical characteristics quoted are for carbon fibre per se, rather than the finished composite material.

I don't see it being much better in terms of stiffness/weight than a hand laid glass fibre design. Even the big advocates of 3-D printed carbon (such as MarkForged) claim the physical properties to be akin to machined aluminium, rather than laid carbon. Autoclaved, moulded pre-preg or vacuum infused is likely to be several times better stiffness/weight and carbon/resin ratios.

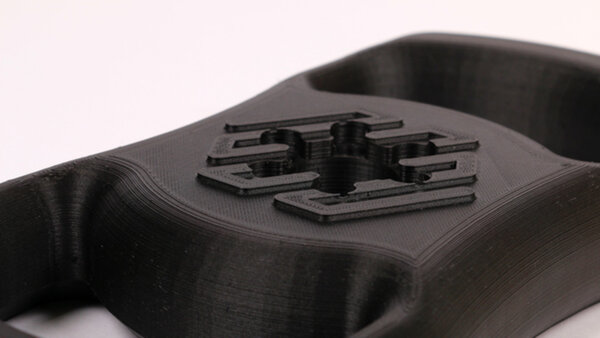

They must be using a lot of surface filler to get that sort of finish on the frame. This is more typical:

Of course, with $19.5 million USD already in the back pocket it's not bicycles they are really thinking about but military & aerospace, and saving the mould, vacuum and autoclave costs balanced against the lower mechanical performance.

All the best,

Looks like the frame is printed laying on its side and hollow, with fibre layers horizontal, (vertical plane on the finished bike) so vertically stiff with just the thermoplastic resin handling sideways and bursting forces...very difficult to handle torsional forces, too.

The fibres are inevitably short, overlapping chopped fibre, compared to woven or non-woven carbon.

Often the physical characteristics quoted are for carbon fibre per se, rather than the finished composite material.

I don't see it being much better in terms of stiffness/weight than a hand laid glass fibre design. Even the big advocates of 3-D printed carbon (such as MarkForged) claim the physical properties to be akin to machined aluminium, rather than laid carbon. Autoclaved, moulded pre-preg or vacuum infused is likely to be several times better stiffness/weight and carbon/resin ratios.

They must be using a lot of surface filler to get that sort of finish on the frame. This is more typical:

Of course, with $19.5 million USD already in the back pocket it's not bicycles they are really thinking about but military & aerospace, and saving the mould, vacuum and autoclave costs balanced against the lower mechanical performance.

All the best,

Attachments

Similar threads

- Replies

- 0

- Views

- 239

- Replies

- 1

- Views

- 309

- Replies

- 0

- Views

- 223