Cheesedisease

Senior Retro Guru

Hello,

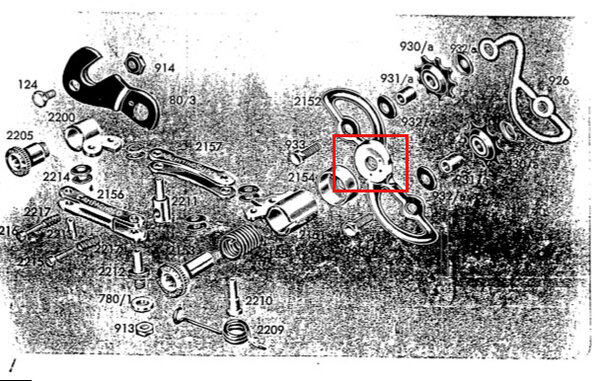

Was servicing an original Record derailleur - Velobase: Campagnolo 1020, Record.. When putting back together I noticed that on the back of the front derailleur cage there are three small holes that fit the end of the spring. I'm wondering which to use, and what difference these could have on the derailleur's performance? My first presumption is that these could effect chain tension as the rotation of the cage in relation to the body would be changed? Catalogue image below highlights what I mean, it's a different model but assembly is same in this regard.

This leads to my second question, in that I'm having a problem with chain tension. Set up is 44/52 and with a 14/15/16/17/18 freewheel, Record 151 BCD crankset, NOS 3/32 Everest chain, NOS Regina Freewheel. The problem is the chain binds a little too much on the larger ring. Have set this up with normal chain length method - wrapped chain round large/large combo and gave an extra two links (one inch), and also then tried added another extra link. Still binds. Do older derailleurs need more chain links - should I just keep lengthening the chain? I'm using modern Jockey wheels in case that could be a problem? These have correct number of teeth, but not sure if these are larger or smaller in diameter, or if that would even matter? Picture of setup also below.

Any advice or help appreciated as always!

Daniel

Was servicing an original Record derailleur - Velobase: Campagnolo 1020, Record.. When putting back together I noticed that on the back of the front derailleur cage there are three small holes that fit the end of the spring. I'm wondering which to use, and what difference these could have on the derailleur's performance? My first presumption is that these could effect chain tension as the rotation of the cage in relation to the body would be changed? Catalogue image below highlights what I mean, it's a different model but assembly is same in this regard.

This leads to my second question, in that I'm having a problem with chain tension. Set up is 44/52 and with a 14/15/16/17/18 freewheel, Record 151 BCD crankset, NOS 3/32 Everest chain, NOS Regina Freewheel. The problem is the chain binds a little too much on the larger ring. Have set this up with normal chain length method - wrapped chain round large/large combo and gave an extra two links (one inch), and also then tried added another extra link. Still binds. Do older derailleurs need more chain links - should I just keep lengthening the chain? I'm using modern Jockey wheels in case that could be a problem? These have correct number of teeth, but not sure if these are larger or smaller in diameter, or if that would even matter? Picture of setup also below.

Any advice or help appreciated as always!

Daniel