Thias

Klein Fan

Hey guys!

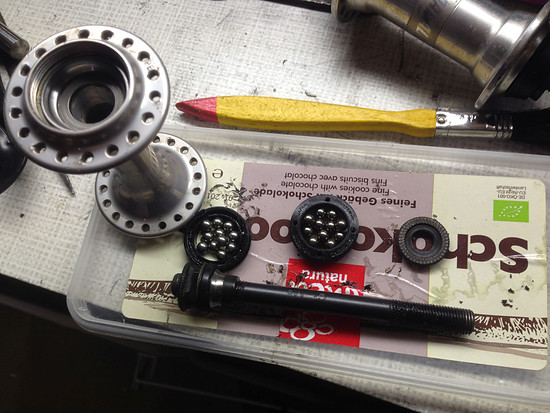

I've been fiddling with my newly aquired lathe. One of the things I had planned trying one day was to redo defective/pitted cones in those shimano hubs.

I have a few M900 XTR and M73x XT hubs that share that problem of pitted cones.

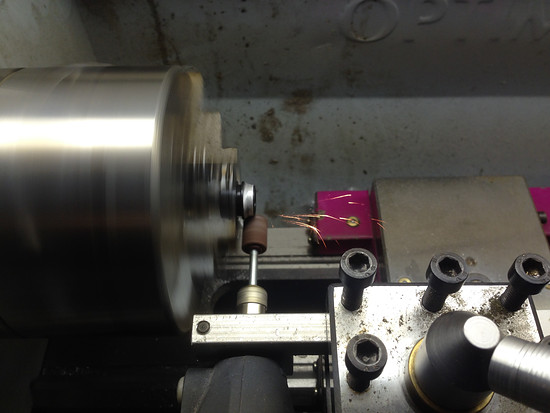

So to test whether or not that is possible, I bodged a mount for attaching my dremel to the lathe.

I then took a very pitted cone out of a Parallax STX hub and first ground, then polished the surface.

Here you can see the first run. The pittings are still there:

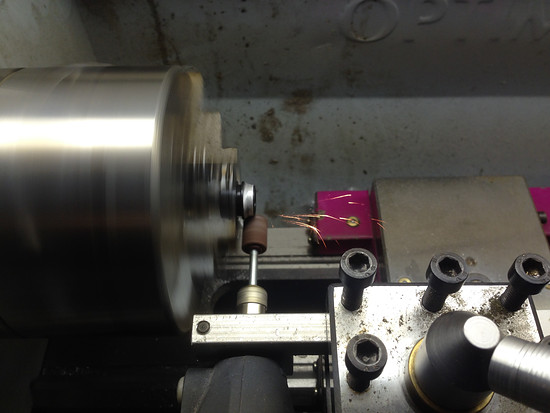

A few runs later...

... until it starts shining...

Sure looks good. But will it be round enough? I dont have the means to measure that.

I'll have to try it out.

(to be continued, ran out of time..)

I've been fiddling with my newly aquired lathe. One of the things I had planned trying one day was to redo defective/pitted cones in those shimano hubs.

I have a few M900 XTR and M73x XT hubs that share that problem of pitted cones.

So to test whether or not that is possible, I bodged a mount for attaching my dremel to the lathe.

I then took a very pitted cone out of a Parallax STX hub and first ground, then polished the surface.

Here you can see the first run. The pittings are still there:

A few runs later...

... until it starts shining...

Sure looks good. But will it be round enough? I dont have the means to measure that.

I'll have to try it out.

(to be continued, ran out of time..)