raidan73

Moderator

Archivist

Retrobike Rider

BoTM Triple Crown

BoTM Winner

Gold Trader

PoTM Winner

98+ BoTM Winner

Rocky Mountain Fan

Brodie Fan

- Feedback

- View

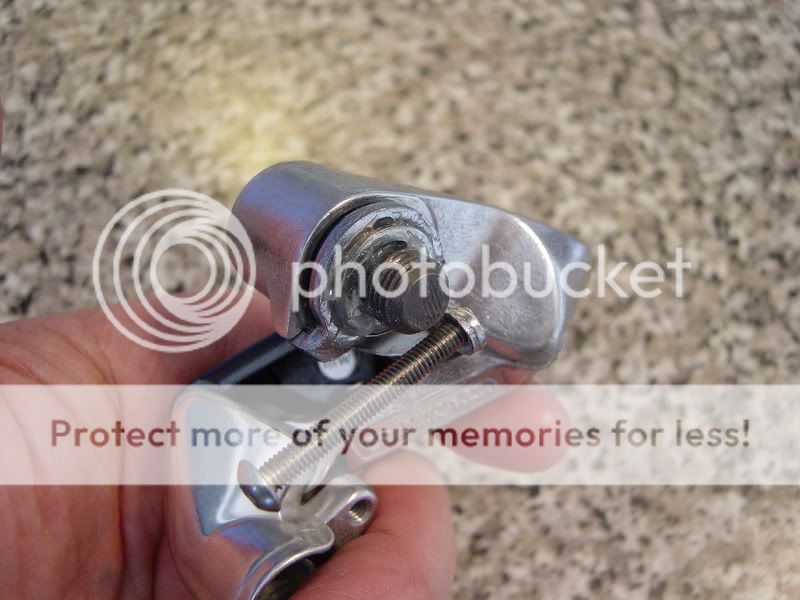

Evening all! I'm after a bit of advice in putting a rear mech back together. I had a rather stiff breakaway bolt which I removed to clean and grease and when I refitted the mech I noticed that there was no tension in the spring. It appears that it has been taken apart in the past and whoever did it has not located the spring correctly - I can see why, because I am unable to rotate it the half turn necessary to get it to locate before refitting the circlip. I'll gladly upload pics to illustrate later but I expect some of you already know exactly what I'm talking about

Any helpful advice appreciated.....

Any helpful advice appreciated.....