As it's a Halifax-built Orange, I'm presuming the aluminium alloy used will be either 6083 or 6061 series, so will not gain any of the 30% or so of lost tensile and yield strength from just 'resting' or natural ageing post-weld. Different matter with 7005/7020 frames.

To regain this strength it would need a comprehensive normalising/quench/realign/age cycle. £500 or so for a one-off by serious heat treatment companies, so really not worth it for this frame.

Best to avoid any oil or even any specialist crack identification dyes...if there is a crack, any penetrants contaminate the fresh material on the inside faces of the crack, which will need extensive cleaning/detergent/degrease/acetone before welding. Fine for aerospace, but not here.

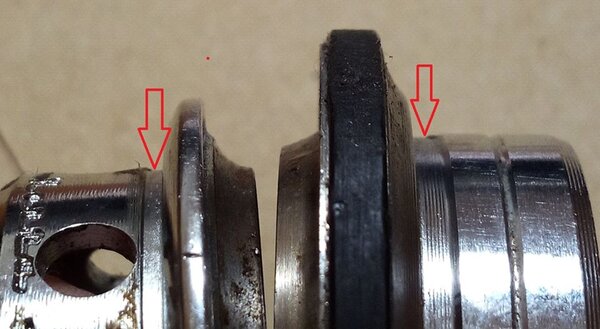

Just remove the cup and have a good look. The cup should pull out pretty easily, without much force, if that is a crack anyway, as it will probably have dissipated all the holding force of the interference fit.

An interference fit external collar would be the best approach to repair, either on its own, or ideally in combination with remedial welding of the crack.

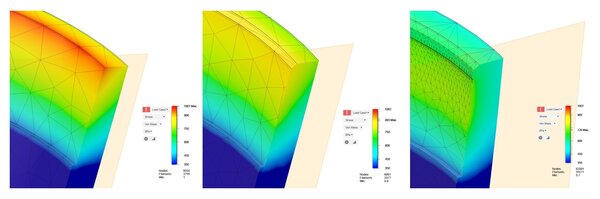

Also, best to ream and chamfer the internal edges of the headtube bore top and bottom back to the looser end of the standard tolerance (33.95 mm (+0.00/-0.05)) and, if you can, get a small relief machined into the headset cups like this:

These two measures combined will reduce bursting force by around 30% to help preserve the headtube for the future.

This is what comes of using a standard originally designed for steel frames on a different material without addressing the likely issues...

All the best,