You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cutting down an XTR chainring spider

- Thread starter dyna-ti

- Start date

Do they have more than 1?dyna-ti":qqcwow5v said:Plus an lbs i know has a nice goldtec on this pattern.

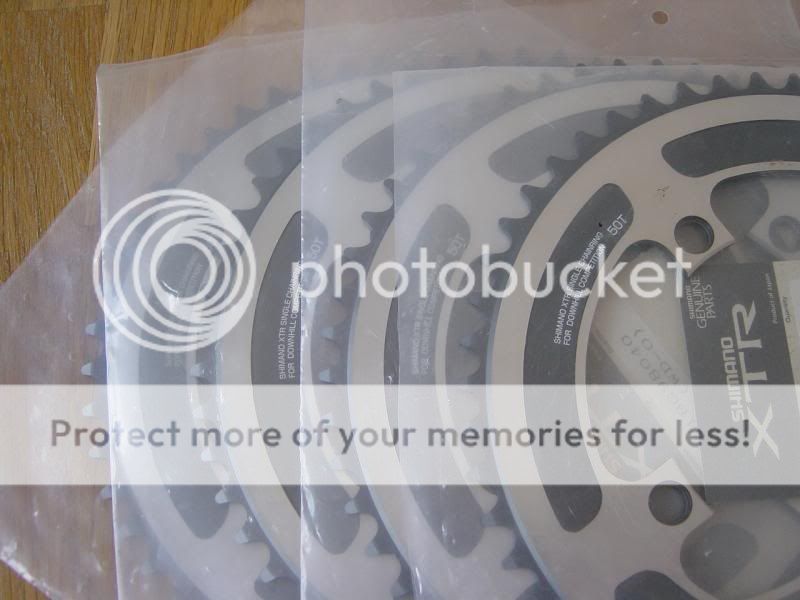

After replying earlier I did a quick Google for 112 bcd rings and found a middle ring on ebay. Took a punt thinking it would go for silly money.........

Just need a nice left arm and inner ring now.......

Sorry WD. Its just a wee spider project, im not actually intending to do anything with it.

Oh aye :? bit quiet about that

I only saw the oneishaw":1kevqq2c said:Do they have more than 1?dyna-ti":1kevqq2c said:Plus an lbs i know has a nice goldtec on this pattern.

ishaw":1kevqq2c said:After replying earlier I did a quick Google for 112 bcd rings and found a middle ring on ebay. Took a punt thinking it would go for silly money.........

Oh aye :? bit quiet about that

Attachments

MRGRUMPY

Senior Retro Guru

Re:

I use m951 cranks on my singlespeed.I got a spider from a set of lx cranks as the spline pattern is the same.

However,the lx spider is much thicker than the xtr item,so I machined it down a bit and,hey presto,straight on,choice of chainrings in all sizes and colours and no creaks or problems for the last 3 months.

I use m951 cranks on my singlespeed.I got a spider from a set of lx cranks as the spline pattern is the same.

However,the lx spider is much thicker than the xtr item,so I machined it down a bit and,hey presto,straight on,choice of chainrings in all sizes and colours and no creaks or problems for the last 3 months.

Snapped off the remaining teeth with a set of moles as the less metal to grind off. then took it back to about 2mm from the lip as a rough guide.

From there im using a belt sander as this is quite soft, not chattery and easier to hold the ring flat against the top with the sander lying on its side. just a matter of turning the ring as you go.

Ill do another pic of the edge after the belt sanders done its work. About 1/2 ways through at the moment. :?

The block ive the ring on for the pic is a carborundum stone. Alloy clogs the wheel and the stone dresses the grinding wheel and removes the alloy particles by grinding the stone itself back.

From there im using a belt sander as this is quite soft, not chattery and easier to hold the ring flat against the top with the sander lying on its side. just a matter of turning the ring as you go.

Ill do another pic of the edge after the belt sanders done its work. About 1/2 ways through at the moment. :?

The block ive the ring on for the pic is a carborundum stone. Alloy clogs the wheel and the stone dresses the grinding wheel and removes the alloy particles by grinding the stone itself back.

Attachments

Similar threads

- Replies

- 61

- Views

- 10K

- Replies

- 1

- Views

- 298

- Replies

- 0

- Views

- 1K